Valuable Evolution in the Craft of Surimi Inherited Over Generations

- Food & Beverage Manufacturing

- 100 Year Company

- Connecting with People

- Environmental Issues

Osaka

Fujikuma Foods Co., Ltd., established in 1917, is a long-standing company in Osaka that has been manufacturing primarily processed fish products using traditional methods. For over 100 years, it has been beloved by many and has brought smiles to its customers.

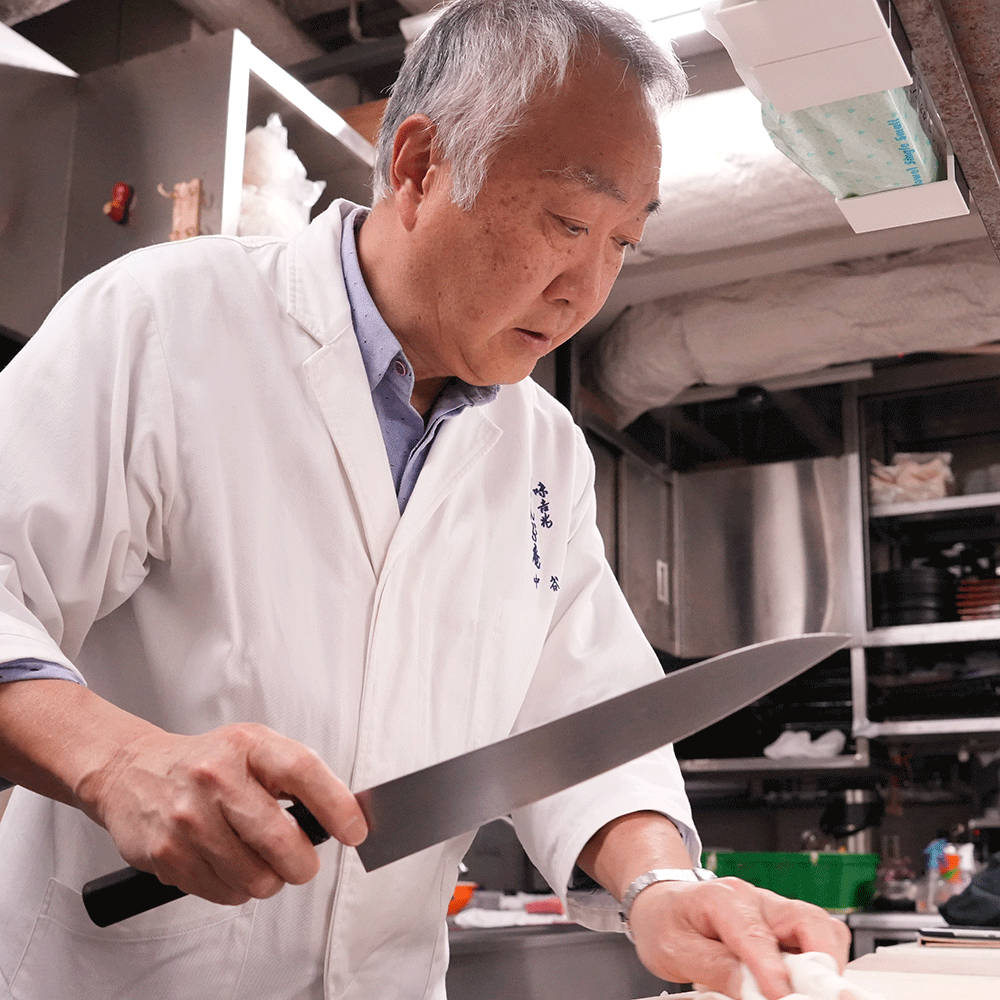

The founding spirit of Kumao Fujita, the first-generation founder, is carefully upheld by the skilled artisans, who continue to use the traditional 'Ishi-usu Method' to grind selected ingredients with care. They even give special attention to the oil used for frying, considering its compatibility with the surimi, as well as its aroma and sheen, to create a truly exceptional product. We spoke with Masafumi Fujita, the fourth-generation president of the company."

PROTAGONIST

Masafumi FujitaRepresentative Director

The History of Fujikuma Foods

The founder, Kumao Fujita, was born in Tokushima Prefecture in the former Awa Province. Driven by a desire to share kamaboko (fish cake) made from fresh fish with as many people as possible, he traveled alone to Osaka in the early Taisho era. After completing his apprenticeship, he opened a shop at the former Tenma Market, where he began producing and selling freshly fried surimi tempura and kamaboko.

During the war, Kumao’s wife preserved his principles and craftsmanship. After the war, their son, who returned home, became the second-generation owner and resumed the business. The shop was later passed on to the third generation, and in 1983, a new location opened at the Central Wholesale Market in Ibaraki City. In 2007, Masafumi Fujita assumed the role of fourth-generation president, marking the current leadership.”

Strengths and Dedication

The company experienced significant changes triggered by the COVID-19 pandemic. As the pandemic persisted, some of their business partners were forced to close, leading Fujikuma Foods to acquire part of their know-how. Building on this, they began developing new products by adding their unique touch.

Large-scale food manufacturers focus on maximizing efficiency and mass production, so artisans do not necessarily need to be present in their factories. These companies commonly use leavening agents to triple the volume of the original ingredients, texturizing agents for a chewy texture, and preservatives to extend shelf life. This approach is standard in large-scale manufacturing.

Fujikuma Foods, on the other hand, bases its production methods on craftsmanship handed down through generations. They outsource certain processes, such as removing impurities from the fish at the fishing port, and adopt machines for tasks where efficiency can be improved. However, they emphasize that the key to their products lies in the “kneading” process. By eschewing automation and using stone mortars to hand-knead, they achieve a fine, high-quality texture. Additionally, they highlight the importance of adding salt when mincing frozen fish meat that has been washed in cold water to remove impurities and then stored.

“The salt causes the proteins to bind together, creating a springy and resilient texture. It’s a simple extra step. While we cannot produce large quantities, we aim to make high-quality products with minimal additives, preparing only the amount needed for each day.”

The fourth-generation president broke away from the low-margin, high-volume business model maintained by his predecessors and raised prices to a more appropriate level.

Inheritance and Conflict

4Masafumi Fujita, the fourth-generation president, took over the family business at the age of 26. After graduating from university, he initially worked at an automotive parts manufacturer, where he learned the basics of professional etiquette, sales, and negotiation. Although he was the second son of the Fujikuma family, it was determined from a young age that he would inherit the business, based on the guidance of a fortune-telling master who had long been close to his father.

Regarding the wholesale business that the third-generation president had developed, Masafumi felt uneasy about the pricing and came to view it as a low-margin, high-volume model. He then began focusing on producing high-quality surimi products, such as oden, prepared foods, and even pet food, aimed at affluent customers and began selling through major companies and department stores.

Observing his actions, his father remarked, “Aren’t the prices of these new products a bit high? Please consider keeping some affordable items so that our long-standing customers will continue to visit us as they always have.” His father, who had been involved in the low-margin, high-volume business for many years, opposed Masafumi’s approach to setting prices at a more appropriate level.

However, Masafumi firmly insisted, “Given the effort we put in, I want to build relationships primarily with partners who acknowledge the value of appropriate pricing and ensure fair profit margins.”

Following the onset of the COVID-19 pandemic, his parents fully retired, and Masafumi (then 50) assumed full responsibility as the head of the company. Along with relocating the factory, he overhauled the staff, beginning anew with an advisor—a craftsman with a similar mindset—who had quietly supported him and shared his values.

“When wholesale is the focus, we are often asked to lower prices in exchange for large orders or to provide sponsorship fees. This approach makes it hard to understand what we’re truly striving for. As I was out searching for new partners who could appreciate our approach, a promising contact emerged.”

The Struggle for Survival

In expanding their product range beyond surimi, the company began focusing on prepared foods, oden, and grilled fish. This led to an invitation from Takashimaya to participate in their Pop-Up Station event, which secured them a spot among the curated items in the “Taste Selection” corner. The company’s surimi products quickly became a hot topic, catching the attention of Takashimaya’s buyers. Soon, they were receiving numerous invitations from department stores and established an in-house team dedicated to event showcases.

“I felt recognized for the work I had been putting in.”

However, Masafumi’s joy was short-lived. With the onset of the COVID-19 pandemic, department stores closed, and even when they reopened, customers were scarce. The events team had to be disbanded, and the factory and shop temporarily ceased operations.

Despite these setbacks, Masafumi continued to pursue product development, aiming to create “delicious items” and “products that bring smiles to everyone”—not limited to surimi alone. Once the pandemic subsided, he rebuilt trust with department store representatives, hired new talent, and reassembled the events team to pursue new opportunities for showcasing their products.

Even in the face of a company crisis, Masafumi’s noble character shines through as he responded with flexibility, upheld his commitment to innovation, and demonstrated resilient perseverance.

Future Challenges

In recent years, fish stocks have continued to dwindle due to overfishing, climate change, and increased fish consumption in China, which has caused fish to migrate northward. Many fish that were traditionally sourced from the East China Sea to Japan are now flowing to China, leading to Japan often being outbid. With Japan’s population on a declining trend and Southeast Asia’s population increasing, Masafumi envisions establishing a new factory in Vietnam in the future. Local surimi products there are mostly soft, meatball-like items with little texture. He expressed a desire to leverage Fujikuma’s techniques to produce high-quality items and hopes to expand factories across Southeast Asia.

In addition, he emphasized the importance of aligning with advice from department store merchandising (MD) experts for product development, aiming to produce items that meet consumer demand and adapt to changing times. He plans to take a comprehensive approach—from sourcing, pricing, and sales methods to display and advertising strategies—to ensure a well-rounded execution.

INFORMATION

Fujikuma Foods Co., Ltd.,

In the Awa Province, now known as Tokushima Prefecture, the founder, Mr. Kumao Fujita, was born with a desire to bring fish cakes (kamaboko) made from fresh fish to more people. With this passion, he moved alone to Osaka in the early Taisho era.

After completing his apprenticeship, he opened a shop in the bustling old Tenma Market, where he began producing and selling freshly fried fish tempura and kamaboko. His use of fresh ingredients and excellent taste quickly gained a reputation, and his small storefront was filled with shoppers every day. Even after the market merged into Osaka City Central Wholesale Market in Fukushima Ward in 1931, he continued his business there.

It is said that his commitment to fresh ingredients was unparalleled. His spirit remains alive today, with a continued focus on handmade production, utilizing the "Stone Mill Method" to carefully grind selected ingredients.

- Founded in

- 1917

- No. of employees

- -

- Website

- https://www.fujikuma.com/

- Writer:

- GOOD JOB STORY 編集部