From Something That “Disappears” to Something That Is “Chosen”:A Business Strategy to Redefine the Seal (Hanko) Market

- Other manufacturing

- Unique Products & Services

- Efforts for the Community

- Creative

Osaka

In Japan’s business and everyday life, hanko—personal seals formally known as inshō—have long played a vital role. Upholding this tradition while diversifying its business through innovative technologies and ideas is Osaka-based Withus Co., Ltd. (hereafter referred to as “Withus”). The company engages in a wide range of activities, from e-commerce-focused sales of hanko to the development and marketing of engraving machines, and more recently, expansion into the growing sealing stamp market.

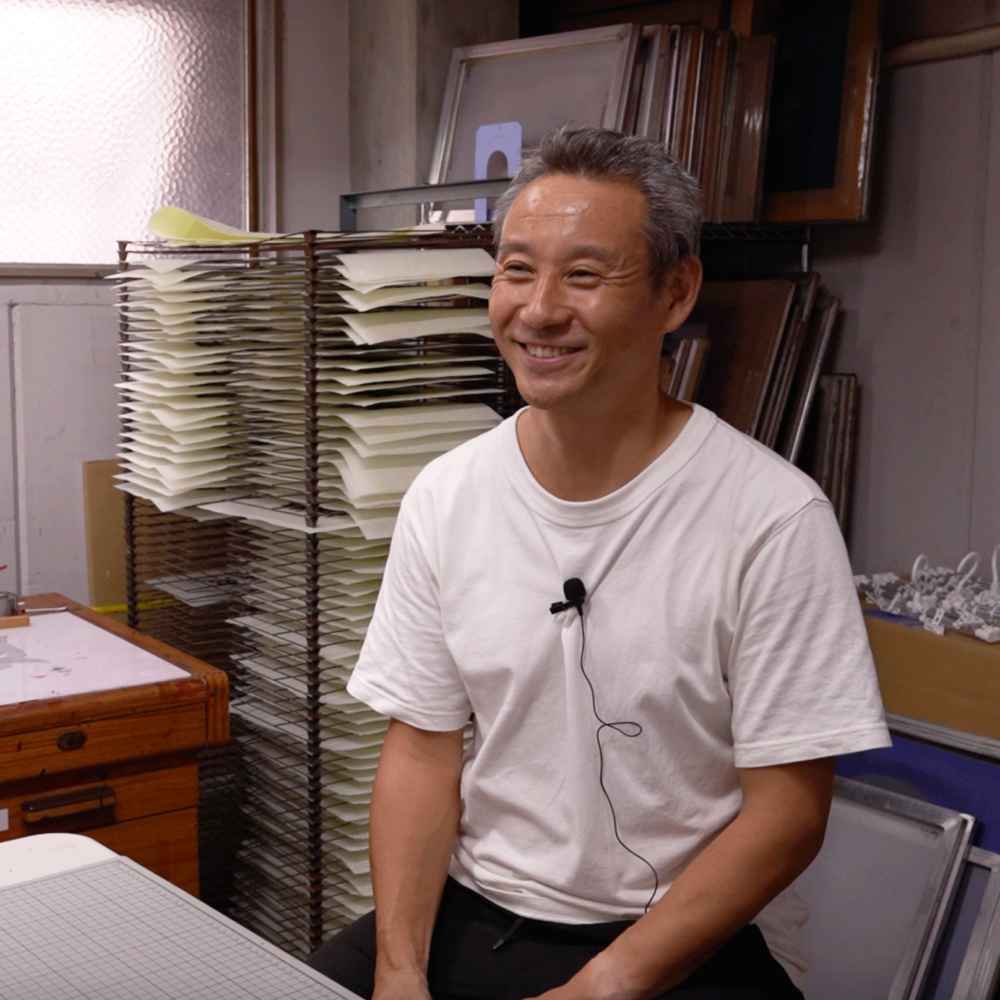

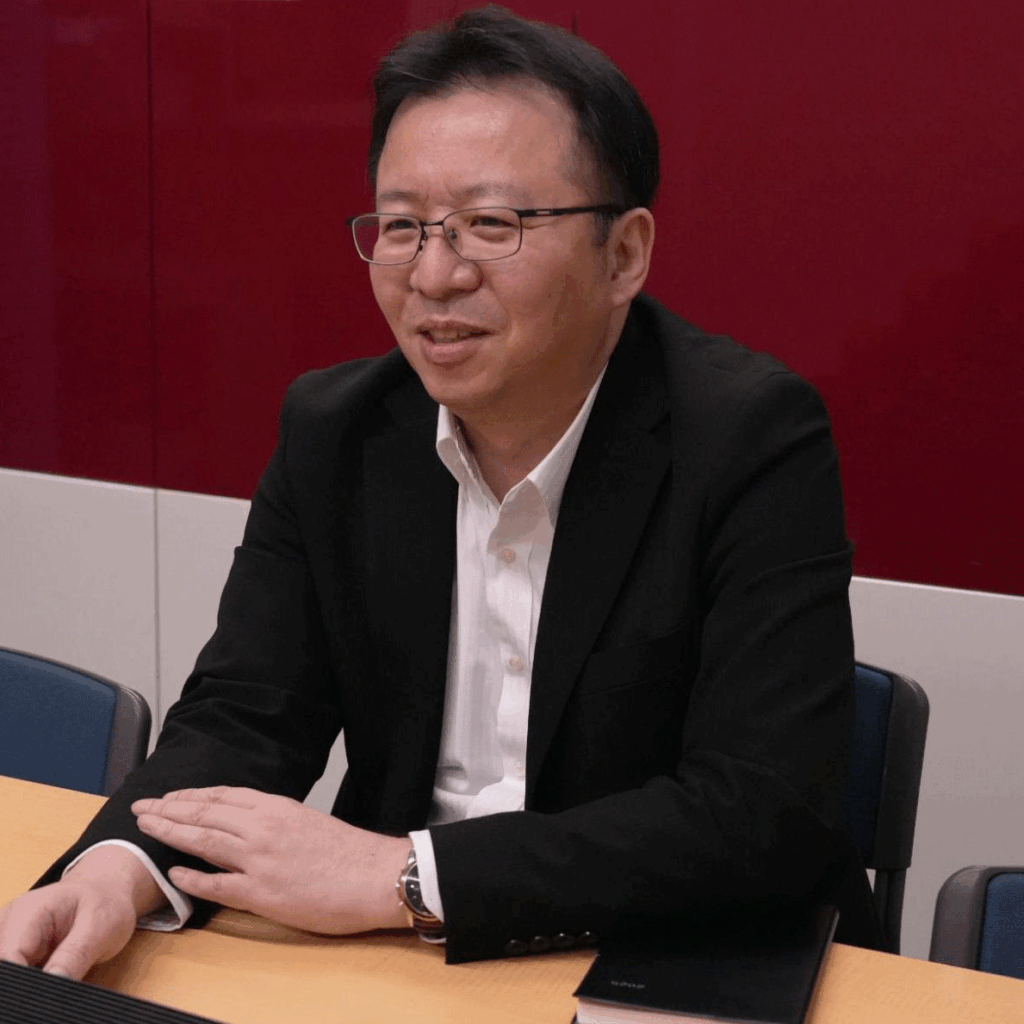

In this article, we spoke with Mr. Atsushi Okumoto, President and CEO of Withus, about the company’s business, its strengths, and the possibilities it sees in overseas markets.

PROTAGONIST

Atsushi OkumotoPresident and CEO

Despite the shift toward a paperless society, the company’s performance continues to show steady growth.

Withus operates under a dual business model: one centered on the manufacturing and sales of seal-related equipment, and the other focused on the retail of game and entertainment products.

In the seal business, the company sells engraving machines to hanko and stationery stores across Japan. It also manufactures hanko in-house, manages retail websites, and supplies materials while providing OEM services to seal shops. In the entertainment sector, Representative Director Mr. Nakahara leads wholesale and retail operations for game-related merchandise, including running directly managed stores that specialize in trading cards and other collectibles.

Some might wonder, “Do hanko still sell these days?” Even in an era marked by a move away from paper, Withus has maintained steady sales growth since its inception. Unlike major industry players, the company started without a long-standing track record or existing assets. Precisely because of this, it has remained unbound by conventional norms and focused on developing products and services from a user-centric perspective.

One of the company’s most distinguishing features is its integrated approach: Withus handles everything from machine manufacturing to retail in-house. Such vertical integration is rare in the hanko industry.

“I don’t feel that demand has dropped compared to the past. Some people may frown upon manufacturers engaging in retail, but the fact that we both produce and sell our products allows us to accumulate expertise and accurately identify what resonates with customers. That’s our strength,” says Okumoto.

By directly reflecting customer feedback from retail into its services and production, the company can make timely improvements to its engraving machines, resulting in a rapid development cycle. This system enables Withus to meet even the smallest needs with precision.

“For example, if a new hanko e-commerce business is launched, and we were only a retailer, that would mean one more competitor. But if that business uses our machines, they become a partner instead. We believe that energizing the industry as a whole will benefit us in the long run.”Amid rapid societal change, Withus is redefining the value of hanko, creating new reasons for them to be chosen.

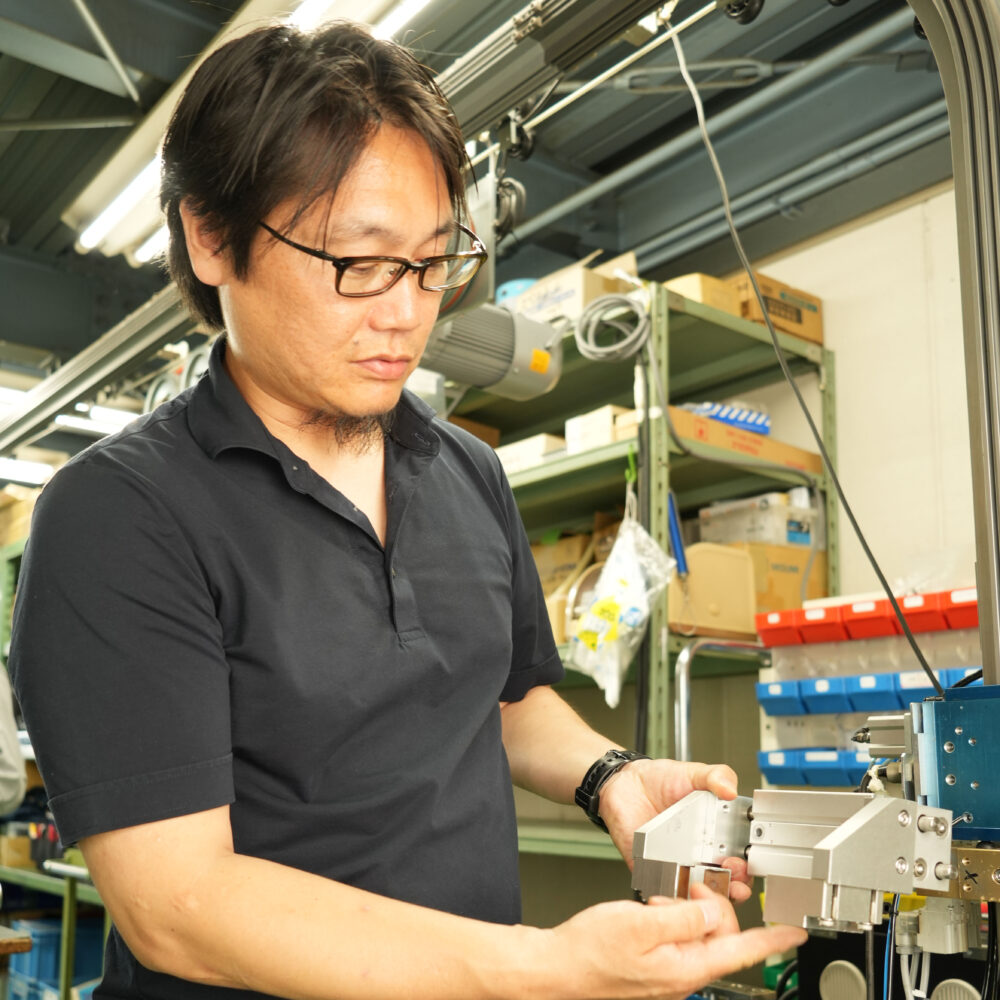

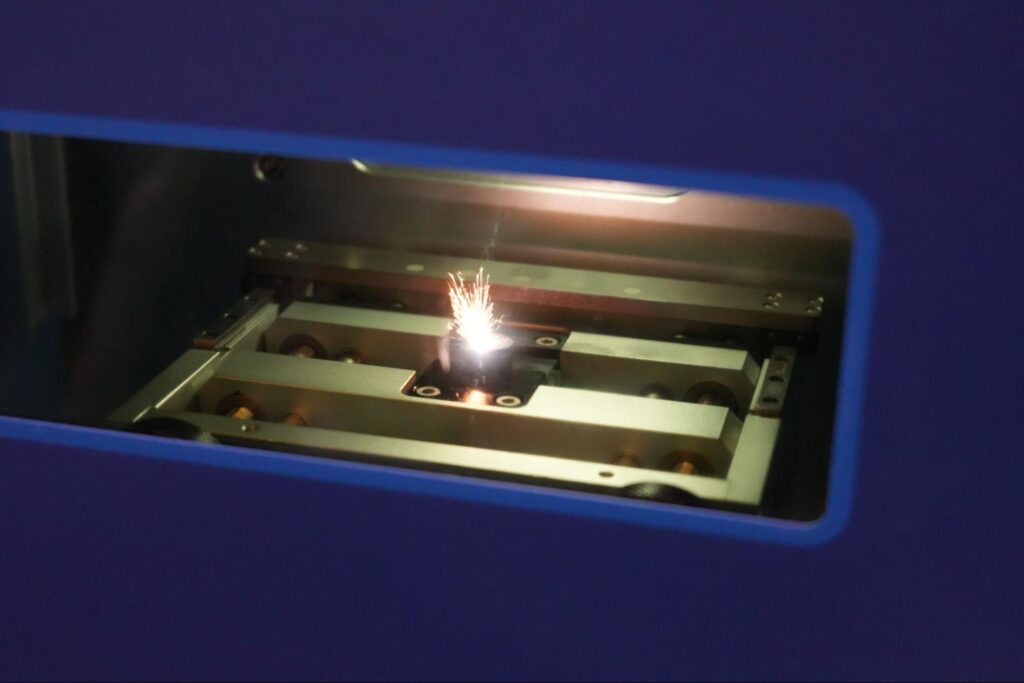

The Innovative Engraving Machine “HO-REST” That Breaks Through the Limitations of Conventional Models

Released in December 2024, HO-REST is an innovative engraving machine that, unlike typical models for seal production, also supports engraving on metal. Moreover, it comes equipped with a dedicated mode for sealing stamps, which have been growing in popularity.

“HO-REST can of course engrave standard hanko, but it’s also compatible with metals like titanium. Unlike hanko, sealing stamps require grooves that allow wax to flow into them. The machine carves with a widened V-shaped entrance on the impression surface, making it easier for the wax to settle. In short, it engraves with a sloped cross-section. Besides that, it’s a versatile machine that can engrave nameplates, wooden tags, and more.”

While hanko engraving typically uses very thin and sharp needles, sealing stamps require thicker, more blunt needles to achieve the appropriate carving depth and shape. HO-REST overcomes the limitations of its predecessors, such as the BIZ50 and Techno Expert, achieving both high-quality engraving and versatility.

Japanese hanko require an extremely high level of precision—for example, fitting five to six kanji characters into a small space while maintaining clear legibility.

“Our engraving machines are manufactured at partner factories overseas. While other Asian countries also have seal cultures, Japan’s standards are on a completely different level. The original specifications simply don’t meet the requirements. That’s why we work closely with our overseas partners to customize both the hardware and software in a way that aligns with our product development goals,” says Okumoto.

Equally important, he notes, is the support system. Simply importing and selling machines is not enough to earn the trust of Japanese users.

“It can’t end with just selling the product. We have to ensure that everything—from usage guidance to maintenance—can be handled entirely within Japan, and that this support is sustainable over time.”

By combining the production capabilities of overseas partners with Japan’s meticulous attention to detail, Withus delivers machines that truly meet the needs of the Japanese hanko industry.

A Business Model Focused on Quality That Cannot Be Easily Imitated

What sets Withus apart is that it is not merely a machine manufacturer. Because the team is directly involved in engraving hanko themselves, they are able to pursue engraving quality with an on-the-ground perspective—considering not just machine performance, but also the ease of preparing artwork and the precision of the final output.

“If you’re a machine manufacturer, of course you know the specs of your machine very well. But in reality, many of them haven’t actually made hanko themselves. No matter how advanced a machine is, making hanko requires a level of skill—and a sense for design. There aren’t many manufacturers who truly understand all of that,” says Okumoto.

The company obsesses over the reproduction of even the finest lines—details most people wouldn’t even notice. That level of precision is only possible because they use the machines themselves on a daily basis.

“When it comes to hanko, we’re not concerned about cheap products from 100-yen shops or mass retailers. Anyone can copy the shape. But the level of quality, the sense of design, the ability to propose new ideas, and the power to communicate—those elements together form a ‘business’ that can’t be imitated.”

Sealing stamps are gaining popularity through social media and stationery events, though the domestic market is still relatively small. Nevertheless, Okumoto sees this trend as an opportunity.

“I think we can create new points of contact by highlighting sealing stamps, which are gaining attention from stationery lovers and designers. Still, no matter how good your product is, it doesn’t mean anything if people can’t find it. Shops that invest in social media and their websites are clearly stronger. On the other hand, if you don’t even have a website and only rely on local flyers, it’s hard to be discovered—even if you start something new.”

With promotional efforts for HO-REST—ranging from websites to brochures and trade shows—Withus is actively showcasing sealing stamps to tap into new customer segments. In today’s market, not only creativity and design, but also the ability to effectively reach and engage customers may become increasingly vital.

Delivering a Seal That Truly Holds Meaning

As digitalization advances, it is true that the opportunities to use hanko have declined. However, the real issue is not with the hanko itself, but rather with the outdated and inefficient procedures that forced people to use seals even when they were unnecessary.

“For example, during the COVID-19 pandemic, there were cases where employees had to go into the office just to get their manager’s hanko, even though they were working remotely. But I think such companies are now almost nonexistent. When hanko are used meaningfully, there are still many people who genuinely want them. Even if the occasions to use them are fewer, I want to continue making seals that people say, ‘I like this one,’ or ‘I want to stamp with this.’”

In fact, on the company’s own e-commerce site, OSITERU, hanko with strong design and originality continue to sell well.

At present, there are no concrete plans to expand into overseas sales. However, Japan’s hanko culture is gaining attention through inbound tourism, and there is clear potential—as seen in the growing popularity of personalized hanko with kanji characters among Western travelers.

With its leading market share in engraving machines, Withus aims to become a driving force that elevates the value of the seal industry as a whole.

“There are very few companies that both manufacture machines and sell hanko. That’s exactly why we believe there’s meaning in what we’re doing. While we haven’t expanded overseas yet, we’re confident that there are markets out there where people would be interested in our products.”

In an increasingly digital world, the key is not simply to “survive,” but to be “chosen.”

How can the value of seals be redefined in this changing era?

All eyes are on Withus as it prepares its next move.

INFORMATION

Withus Co., Ltd.

As a manufacturer of seal engraving machines, we have been supplying engraving machines to stamp shops across Japan, achieving the No.1 industry shipment volume from 2007 to 2019.

At our seal online store “Hanko de Hanko,” skilled artisans who are highly familiar with our in-house engraving machines use ultra-fine needles and various engraving techniques, and further perform detailed hand-finishing, successfully delivering a quality that surpasses even traditional hand-carving.

- Founded in

- 2008

- Website

- https://www.w-us.co.jp/

- Writer:

- GOOD JOB STORY 編集部