With a deep commitment to authentic flavor and time-honored craftsmanship, Kanekusu Suisan Co., Ltd. delivers the finest Akashi octopus.

- Food & Beverage Manufacturing

- Other manufacturing

- 100 Year Company

- SDGs & Sustainability

- Historic Products & Services

Hyogo

Have you ever tasted octopus without any additives? The octopus boiled by Kanekusu Suisan Co., Ltd. (hereafter referred to as Kanekusu) is seasoned solely with its natural umami—and it is simply exquisite.

Kanekusu has been engaged in the processing and sale of Akashi octopus for over a century. Since its founding in 1921, the company has grown alongside the local fishing industry, steadily evolving in response to the changing times.

“We take great pride in Akashi octopus and hope to pass it on to the next generation,” says Yosuke Kusu, the fourth-generation successor candidate. Guided by this sentiment, the company continues to walk the path of blending tradition and innovation.

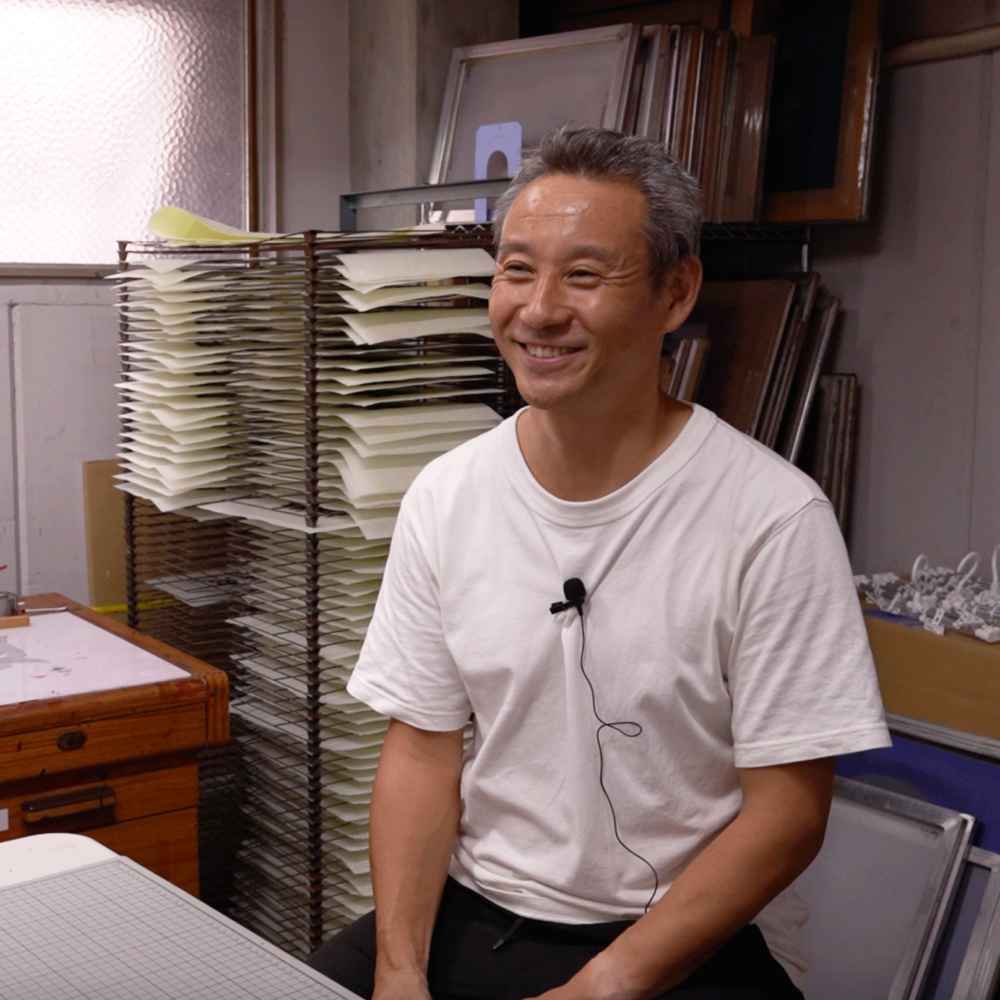

PROTAGONIST

Yosuke KusuFourth Generation

The finest Akashi octopus, with skin that bursts at the very first bite.

Kanekusu Suisan Co., Ltd. is a company that centers its operations on the processing and sale of Akashi octopus, a specialty product of the local region. The company primarily handles madako (common octopus) caught near the Shikanose fishing grounds in the Akashi Strait, branding it as Akashi octopus.

The octopus’s firm texture and the rich umami that intensifies with every bite are the result of two factors: the powerful currents of the Akashi Strait that strengthen the meat, and the abundant supply of shrimp, crab, and other prey in the area.

Once the fishermen return with their catch, the octopus is subjected to strict freshness control at the port by Kanekusu’s staff. Each one is swiftly processed by skilled artisans who carefully determine the precise amount of salt and boiling time. Through the combined expertise of both fishermen and artisans, the optimal texture of the octopus is fully brought out.

“Our boiled octopus at Kanekusu offers a crisp, almost snapping sensation as the skin bursts the moment you bite into it. Many people are surprised by this texture when they try it for the first time, but this is actually the authentic texture of octopus. You won’t find octopus with this kind of firmness anywhere else. We receive a baton of flavor from the fishermen and the workers at the port, and we carry that forward. I’ve been eating this rare and delicious octopus since I was a child, and it wasn’t until I began working here that I realized just how luxurious that experience was.”

In addition to boiled octopus, Kanekusu Suisan Co., Ltd. also produces dried fish products. The raw fish used for drying includes species such as hokke (Arabesque greenling) and pacific saury from Hokkaido, and mackerel from Norway. These dried fish products are mainly supplied to large retailers, but in recent years, the company has also begun exploring new channels such as crowdfunding, e-commerce platforms, and direct sales.

From the amimoto—the fishing master who leads the local fishermen.

The origins of “Tako Shō,” a brand of Kanekusu Suisan Co., Ltd., date back to 1921. Keiichi, the founder and great-grandfather of Yosuke Kusu, initially processed and sold dried sardines made from the locally caught iwashi (sardines). Acting as an amimoto—a central figure who handled the fish brought in by local fishermen—he worked in close collaboration with the community.

However, because fishing seasons vary depending on the species, he began handling octopus during the off-season. While the company originally focused almost entirely on dried sardines, today, its main business revolves around dried fish and octopus.

“My great-grandfather was light on his feet and full of curiosity, so I heard he even worked in agriculture alongside his main business. Through that, he deepened his ties with local fishermen and eventually began a processing business using locally caught fish,” says Yosuke Kusu.

During the second generation, sardine fishing declined due to the ban on whaling. As whales are natural predators of sardines, their population grew, and sardines became increasingly scarce. Around that time, they learned of a custom in Wakayama of eating dried saury. So, they began catching saury that migrated south from Hokkaido, butterflied them, dried them, and sold them. This product drew nationwide attention, and Akashi eventually came to dominate 80 to 90 percent of the market, becoming a major industry.

“At that time, fish were still plentiful. For example, Numazu was famous for horse mackerel, and Akashi for saury. It was that kind of era, and I heard the second generation focused heavily on dried fish. Back then, fishing and processing were deeply connected, and the entire region was thriving.”

In the third generation, the company remained flexible in adapting to changes in the marine environment while maintaining the scale of operations. The processing facilities were optimized to run efficiently with a small workforce, enabling stable production while maintaining high quality.

Today, Yosuke Kusu, the fourth-generation successor candidate, is not only engaged in the production of boiled octopus and dried fish but is also devoting himself to rebranding efforts aimed at enhancing the value of the Kanekusu brand.

The key to deliciousness lies in the balance of salting and boiling!

As a child, Yosuke Kusu often played near the auctions where his father sourced fish, making the sea and seafood a familiar part of his daily life. He is the youngest of four siblings, with one older sister—making him the third son. Initially, it was expected that the eldest son would take over the business, but the eldest declined early on. Later, the second son also chose a different path. This led Yosuke to start considering his own future around the time he was in junior high school.

“By the time I was about to graduate from high school, I had decided to go into this line of work. I liked eating fish, and honestly, I wasn’t that smart, so I didn’t think I could get into a good university,” he says with a laugh. “My father told me, ‘You don’t have to do it. You can shut it down if you want.’”

However, once he returned home and began working in the business, he faced numerous challenges. One of the most difficult issues was preserving the quality of boiled octopus during freezing and thawing. The well water used for boiling and rapid cooling is exceptionally hard, with a hardness of 800. This water is also considered a crucial factor in bringing out the deliciousness of Kanekusu’s octopus. The artisan techniques that enhance both the texture and flavor also play a vital role.

“If octopus is overboiled, it becomes tough and loses its flavor. It depends on the size, but for Akashi octopus, the perfect boil is achieved by ‘leaving a 1-millimeter core’ in the center. Just a one-second difference in boiling time can result in undercooking or overcooking. Boiling a large number of Akashi octopuses—each differing in size and shape—perfectly and uniformly is an incredibly difficult task. This is something machines can never replicate. It is a masterful technique that only the seasoned artisans at Kanekusu can perform.”

Once boiled, each octopus is individually salted and massaged. During this process, water is added or removed to eliminate excess moisture while preserving the umami. This level of control ensures a concentrated flavor. It is said that no other manufacturer carries out this process. In fact, this unique salting method is considered Kanekusu’s greatest strength.

In general, when processing octopus, alum is commonly used to protect the surface of the flesh. However, the use of alum tends to dull the color of the octopus, which then leads manufacturers to add coloring agents to restore its appearance. At Kanekusu, no alum or other additives are used at all.

“Using alum to protect the surface of octopus is standard practice—it’s nothing special. But I found that alum alters the octopus’s natural flavor, so I decided to stop using it. I thought it was acceptable if the skin peeled or got slightly damaged as a result, and gave it a try. What I found was that freshly caught octopus—those landed that very day—wasn’t significantly affected. That’s when I decided to go completely additive-free.”

This bold decision earned the trust of customers and contributed greatly to the successful branding of Kanekusu’s Akashi octopus. Around that time, a growing trend was emerging that viewed food additives negatively, which also played a key role.

”Adding alum gives the octopus an unnecessary smell. We wanted to keep the natural aroma of the octopus simple and consistent, without any variation in quality. To us, the octopus we handle isn’t just food — it’s a living creature. That’s why we’ve pursued a way to let the true character of the octopus come through, and the result is octopus made without any additives.”

“Kanekusu’s octopus is expensive!”

The natural flavor of the octopus can be enjoyed just as it is. Despite the higher price point, more and more repeat customers are choosing Kanekusu’s octopus. While there are certainly customers who appreciate its value, Yosuke Kusu has felt that the true commitment behind Kanekusu’s octopus has not been effectively communicated.

“When we participate in events at department stores, people—both our business partners and customers—often say that the Akashi octopus my father prepares is incredibly delicious. That was something I was truly proud of. However, that’s feedback from the end consumers. In the seafood industry, frozen Akashi octopus sourced by other manufacturers is placed on supermarket shelves right next to ours. So buyers often say, ‘Kanekusu’s is more expensive, isn’t it?’ That made me want to spread the word about the quality and dedication behind our products, and that’s when I began putting serious effort into rebranding.”

To communicate Kanekusu’s dedication more clearly, Yosuke turned to crowdfunding. Unlike traditional retail channels, crowdfunding made it possible to directly convey the company’s unique practices—ones that no other manufacturers adopt.

Typically, when sourcing octopus, the only available options are either live octopus or fully boiled. There is no in-between. Recognizing this gap, Kanekusu developed a product that was pre-treated—salted and prepared—before being packaged. Unexpectedly, this product became a huge hit among chefs at high-end restaurants. Boiled octopus tends to become tough when deep-fried as tempura, but Kanekusu’s pre-treated octopus can be used right out of the pack with no additional preparation. It earned a reputation for being incredibly easy to use.

“Everyone’s made takoyaki before, right? Most people probably buy boiled octopus for it. But when you make takoyaki with boiled octopus, it gets reheated, making it tough and drawing out the umami. When people talk about takoyaki, they focus on the gooey batter or the sauce—rarely on the octopus itself. From the perspective of someone who loves octopus, it’s disrespectful to treat the octopus as an afterthought,” he says with a laugh.

What Yosuke proposes is to use raw octopus in takoyaki. Not just as a ‘flour-based snack,’ but as a dish where the octopus bounces with umami inside the soft batter—a truly delicious takoyaki. One can’t help but want to try it and taste the difference.

Toward sustainable fisheries that endure beyond a century.

Kanekusu aims to contribute to sustainable fisheries. In recent years, significant changes in the ocean have led to a noticeable decline in fish populations—an issue that the fishing industry is increasingly concerned about.

“Compared to ten years ago, the catch volume of Akashi octopus feels like it has dropped to about one-eighth. That’s why the price per octopus has gone up. But we don’t want a situation where only the wealthy can afford to enjoy delicious octopus. Our goal is to reflect our craftsmanship in the price while still making our products available at affordable prices in supermarkets. The ideal is for people to be able to buy Kanekusu’s octopus whenever they want to.”

The restoration of marine resources is no longer just a local issue—it has become a national challenge for Japan. As one approach to this problem, Kanekusu is making a conscious effort to avoid handling undersized octopuses.

“Octopuses are considered adults from around 500 grams. That’s why we basically only handle those over 500 grams. By doing so, competition naturally arises in that weight range, which should lead to higher prices. I hope we can create an environment where catching larger octopuses is more beneficial for the fishermen than catching smaller ones. Ideally, I’d like to see the current 100-gram catch limit raised to 500 grams, implemented as a national policy.”

Such is Yosuke Kusu’s love for octopus that he has even published a photographic art book featuring them.

“To me, octopuses don’t just look delicious—they look beautiful. When I see them in that beautiful state, and then eat them, I honestly feel like I’m experiencing a level of deliciousness that no one else can. I’d be happy if others could replicate that same experience. The photo book is meant to prepare people mentally before eating. I genuinely believe that Kanekusu can help save the world through octopus,” he says with a smile.

As for his recommended way of enjoying octopus: simply chopping up boiled octopus. Thanks to the natural saltiness of the sea, just a touch of olive oil or sesame oil is enough to make it delicious.

Kanekusu Suisan Co., Ltd. sees its mission as “bringing smiles to people’s dining tables through beautiful Akashi octopus.” With that belief in mind, the company continues to take on the challenges of the next hundred years, building on the tradition and craftsmanship passed down through four generations.

INFORMATION

Kanekusu Suisan Co., Ltd.

Boiled to perfection using century-old techniques of master octopus craftsmen, our one-of-a-kind Akashi octopus is nurtured by the fierce waves and abundant blessings of the strait.

To continue delivering the authentic flavor of true Akashi octopus.

We are Kanekusu Suisan.

- Founded in

- 1921

- Website

- https://kanekusu.com/

- Writer:

- GOOD JOB STORY 編集部