A Next-Generation Manufacturing Created by 66 Years of History Active Technological Innovation and Free Exchange of Ideas

- Metal mining

- Steel industry

- SDGs & Sustainability

- Connecting with People

- Considering Earth's Resources

- Environmental Issues

Osaka

Nankai Molde Co., Ltd., headquartered in Sakai City, Osaka Prefecture, celebrated its 66th anniversary in 2024. As a multifaceted "manufacturing trading company," it has thrived through the Showa and Heisei eras, with two main pillars: mold manufacturing and material sales. While leveraging its long-standing achievements and experience, it is currently engaged in the development of new products and challenges technological innovation.

We spoke with Ms. Chisato Fukuhara, the third-generation president, who values the principles inherited from her predecessors and focuses on employee education and social contribution.

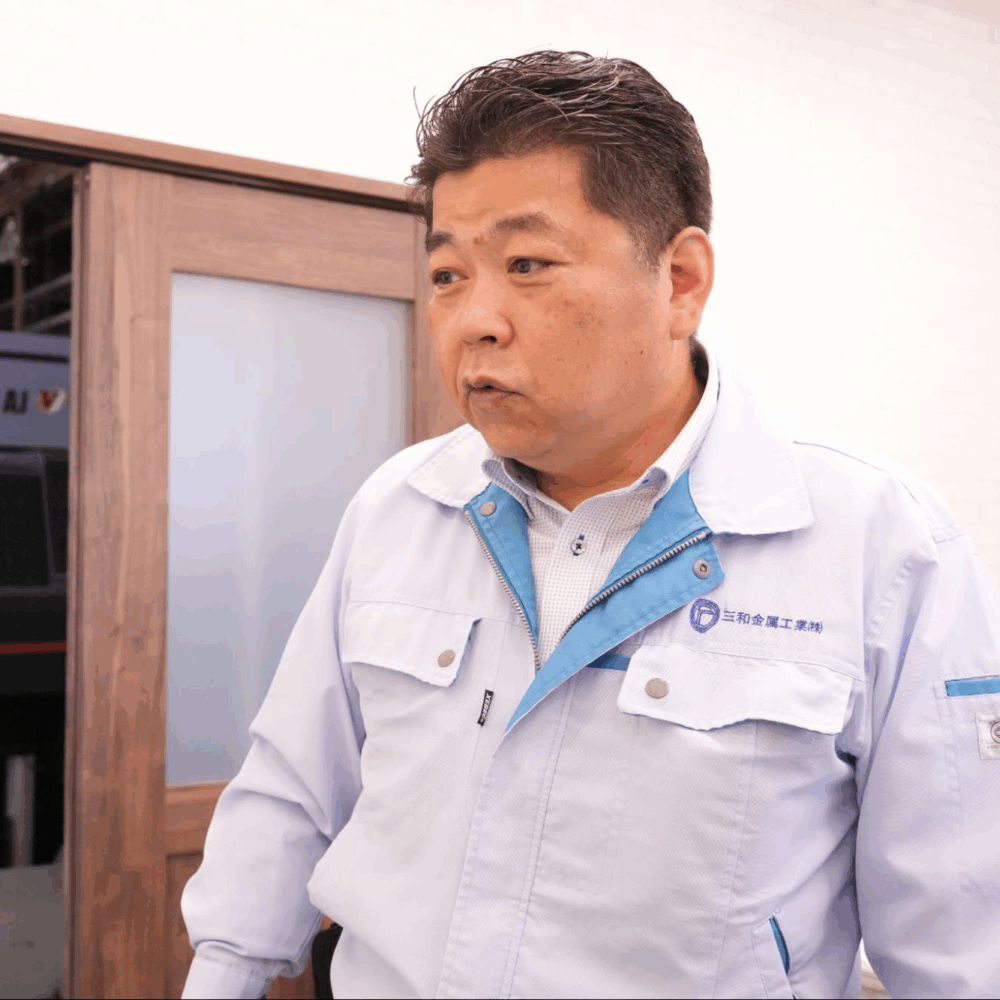

PROTAGONIST

Chisato FukuharaRepresentative director

Founding Background and Inherited Corporate Philosophy

The founder is the grandfather of Ms. Chisato Fukuhara.

The founder is the grandfather of Ms. Chisato Fukuhara.

After the end of the war, driven by a strong desire to start a business, he moved alone from Hiroshima to Osaka. He worked as an apprentice while acting as a broker, buying and selling surplus steel materials. Through this, he started selling mold materials, gradually building up small jobs until he was able to establish the company.

“At the beginning of the company, my grandfather handled structural steel materials widely used in general structures, such as SS material (rolled steel for general structure) and SC material (carbon steel for machine structure), which are considered the basics of steel. Later, during my father’s era, the desire to survive by specializing in something and the dream of becoming a company deeply involved with automobile manufacturers led to a shift in the business towards handling molds for hot forging products, commonly used in car and truck parts,” she explained.

By focusing on the manufacturing and sales of molds related to the automotive industry, they were able to engage with many large companies.

When the predecessor, her father, was dealing with a mold manufacturing company that was struggling financially and on the verge of bankruptcy, he made a crucial negotiation. “Even if your performance declines, we will continue to supply materials to you until the end. If you go bankrupt, could we take in your lead-class technicians?”

Eventually, the partner company went bankrupt, and many excellent technicians joined their company. They were then able to develop mold manufacturing at the same quality level as major manufacturers. “Thanks to those technicians, who are still working hard with us, teaching us the manufacturing processes required to achieve high-quality standards, our business rapidly expanded,” said Ms. Fukuhara.

Without those skilled technicians, it might have been difficult to quickly join the ranks of the manufacturing sector. The company now engages in mold manufacturing (50%), mold material sales (40%), and maintenance services related to molds (10%). Molds are essential metal forms used in the production of parts such as those for cars and are crucial in the manufacturing industry.

The company’s core values and perspectives, such as who the company exists for and how it contributes to society, are passed down from the president to each employee, reflecting the company’s high level of harmony.

Looking Ahead 10 Years

The company values internal communication and adopts a flexible approach when receiving new project proposals from clients, always ready to give it a try and see how it goes.

“The company’s culture is to find a way to handle requests that seem impossible for us. Conversely, just because we have our own products doesn’t mean we must sell them. We can connect clients with other companies and sell their products instead,” said Fukuhara.

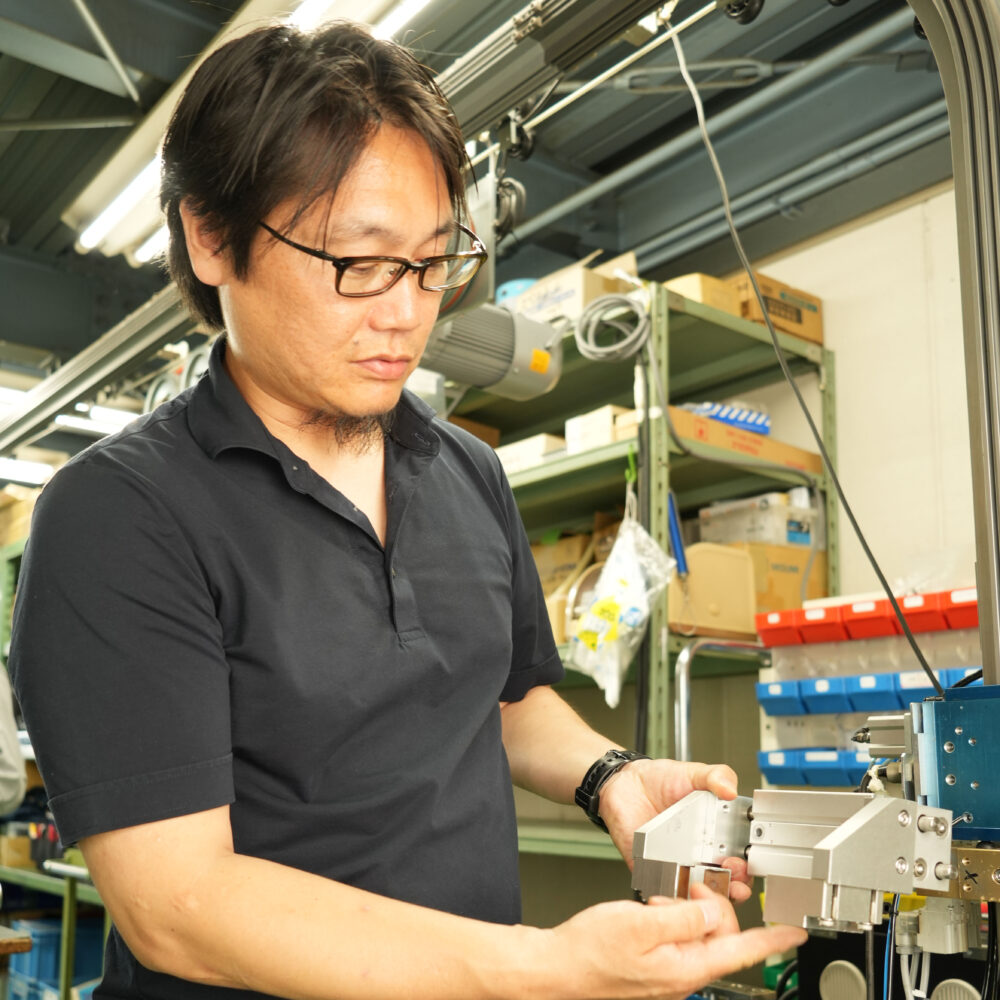

In the future, they envision developing products not only for corporations but also for individual consumers. Otsuka, a company employee, stated, “As craftsmen, we come up with many ideas, such as making plates, creating LED lights, or designing new things. We find it exciting to think about and assemble these ideas. This process sharpens our skills and creates a synergistic effect. Molds are tools for making the final products, so we take great responsibility in this. If we could bring at least one well-known product to market in the BtoC sector, it would be a great success for us as a manufacturing company.”

They are eager to apply their past mold processing techniques and leverage their established technology to innovate in the development of general products.

There are many types of molds, and the ability to create products beneficial to society will depend on future advancements. “Of course, we intend to continue as we have been. We aim to expand the range we can tackle, build our track record, and solidify our structure. Our company has different characteristics and strengths depending on the office and employees, but moving forward, we aim to unite as one team,” said Fukuhara.

The company introduced a blue laser device in 2021, which has a high absorption rate for various types of elements, to implement new technology development internally. They are working on creating new technologies, such as copper alloy parts and welding tools, that can be used not only in the automotive industry but also in construction and medical fields.

Additionally, in terms of training new employees, they strive to convey the company’s philosophy and ensure that both technical and sales staff undergo factory training.

Eighty percent of the company’s total sales come from the manufacture of automotive molds. However, they are now facing an era of great change. To maintain their workload over the next ten years, they plan to flexibly expand their sales range to acquire new customers, improve their original technologies, laser technology, and enhance their maintenance technology as added value to support existing customers.

Building Trust with Customers

In recent years, the importance of a circular economy from the perspective of SDGs has increased, and it is required to engage in eco-friendly efforts such as reducing and recycling. The company is also implementing two measures as part of its business.

The first measure involves not disposing of used molds as scrap iron but regenerating them as mold materials to utilize alloys and rare elements such as cobalt and nickel.

The second measure is to reduce CO2 emissions by regenerating discarded molds from customers through overlay welding, making them reusable multiple times.

“I always share this message with new employees: almost everything essential for daily life involves molds for its production. Molds themselves can be made anywhere if one decides to do so.

However, what customers seek most are aspects like how distribution manufacturers or companies deliver molds as part of their service plans, the extent of quality assurance, the approach to sales, handling of delivery deadlines, measures for dealing with defects, and the disposal or recycling of scrap.

While the molds themselves are not rare, it is crucial to build trust through sincere interactions. This is a time-consuming process but an important point that cannot be easily replicated by other companies,” said President Chisato Fukuhara.

INFORMATION

Nankai Molde Co., Ltd.,

We are not only a trading company that supplies mold materials but also a manufacturing company with the capability to process and create molds and jigs. As a company that develops these businesses, contributing to social sustainability is important.

In particular, to make effective use of valuable resources like special steel used in steel materials and molds, we are focusing on "zero-emission" initiatives.

We compact and mold chips generated during material processing and regularly collect and sort used molds from customers' factories, providing them as raw materials to special steel manufacturers.

- Founded in

- 1958/12

- No. of employees

- 170

- Website

- https://www.nankaikozai.co.jp/

- Writer:

- GOOD JOB STORY 編集部