Differentiation Through Custom-Made Products Showcasing Artisan Skills – 70 Years of Expander Roll Manufacturing

- Industrial Machinery Manufacturing

- successor

- Creative

Osaka

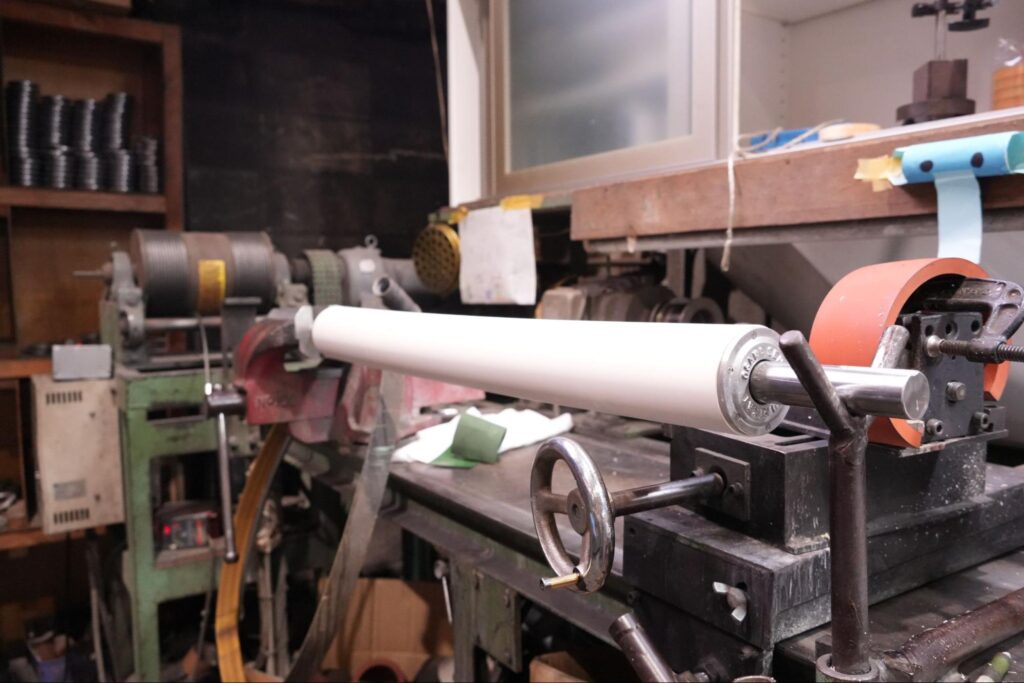

OSAKA SENSHOKU MACHINERY CO.,LTD. (hereafter referred to as OSAKA SENSHOKU MACHINERY) manufactures expander rolls, which have a curved shape. The word "expander" means "to expand," and due to its resemblance to a banana, these rolls were once referred to as "banana rolls."

Expander rolls are used to remove wrinkles that form during the production process of items such as toilet paper, printing paper, and fabrics. By passing the materials through the curved roll, these wrinkles are smoothed out, making expander rolls an essential component in the production of high-quality sheet products.

Currently, only three companies in Japan manufacture this product. As one of them, OSAKA SENSHOKU MACHINERY boasts a history of over 70 years and leverages its strengths in this niche market.

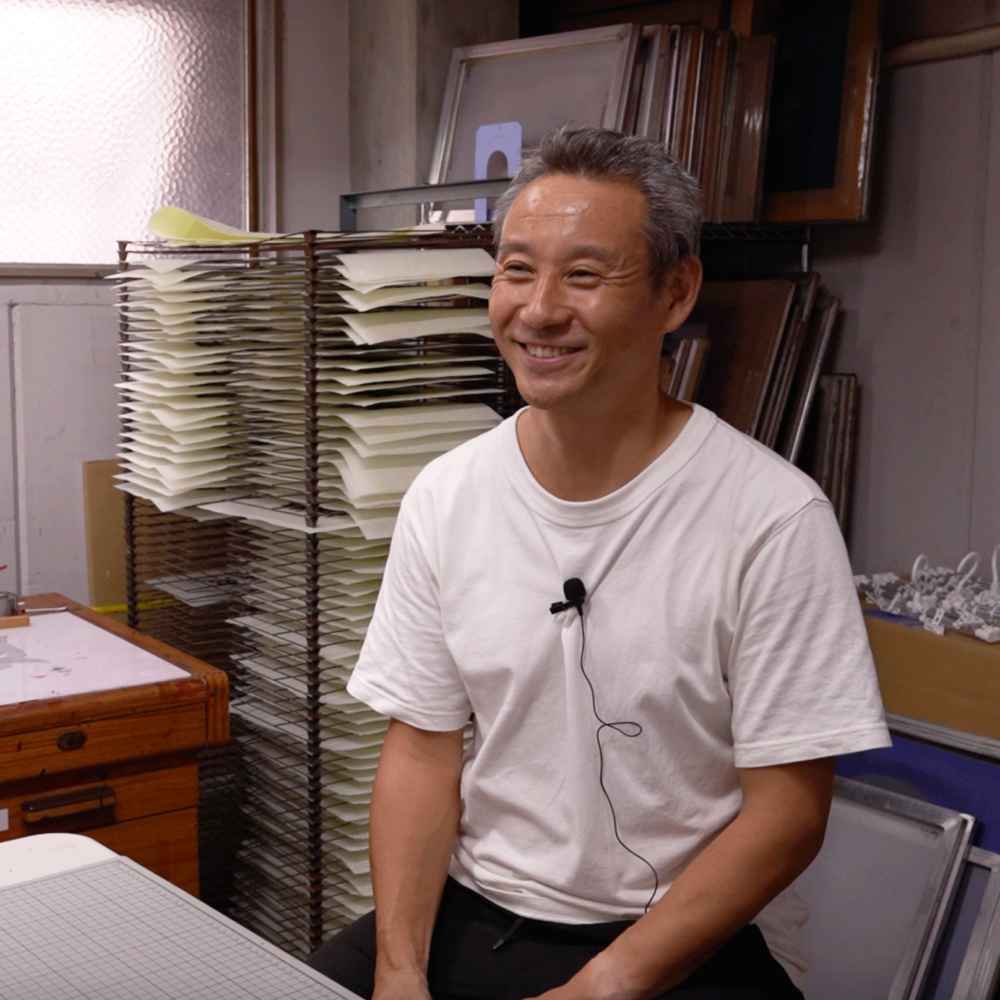

For this article, we spoke with Mr. Satoshi Yamamoto, President and CEO of OSAKA SENSHOKU MACHINERY CO.,LTD.

PROTAGONIST

Satoshi YamamotoPresident and CEO

Shifting from Textile Machinery Manufacturing to Expander Roll Production

OSAKA SENSHOKU MACHINERY CO.,LTD. was founded in February 1951. Initially, the company operated under the name “Fuyuki Ironworks,” focusing on textile machinery manufacturing and establishing itself as a group of engineers supporting the local industry. However, during the production of dyeing machinery, they encountered an issue where wrinkles formed in sheet products.

“At that time, during an overseas inspection, we discovered the existence of curved rolls. Inspired by this, we developed Japan’s first expander roll. Initially, we collaborated with other companies in the industry to advance technological development, but eventually, each company pursued its own independent approach. Today, only three companies in Japan manufacture expander rolls.”

In its early years, OSAKA SENSHOKU MACHINERY primarily manufactured and sold dyeing machinery. However, with the decline of the textile industry in the 1990s, the company fully shifted its focus to expander roll production. While conventional straight rolls function by using bearings to drive rubber-coated rolls, which are rotated by a motor, OSAKA SENSHOKU MACHINERY’s expander rolls are designed to minimize the use of drive mechanisms, allowing for free rotation. This design enables the sheet and roll to rotate smoothly as a single unit, effectively preventing misalignment of the sheet.

“Today, expander rolls are used in cutting-edge industries such as battery production and semiconductor manufacturing. Additionally, the aluminum foil that people use in their homes is processed with this technology to remove wrinkles before being sold. Most people wouldn’t even think that machines are used to eliminate wrinkles in products like toilet paper or aluminum foil during manufacturing.”

Although similar technologies exist, OSAKA SENSHOKU MACHINERY’s expander rolls offer superior precision and lighter rotation, ensuring stability in sheet product production lines. This achievement results from continuous improvements to the technology originally developed for textile machinery. While large-scale expansion of distribution channels is challenging due to the craftsmanship involved, the company remains committed to producing high-quality products that maximize the expertise of skilled artisans.

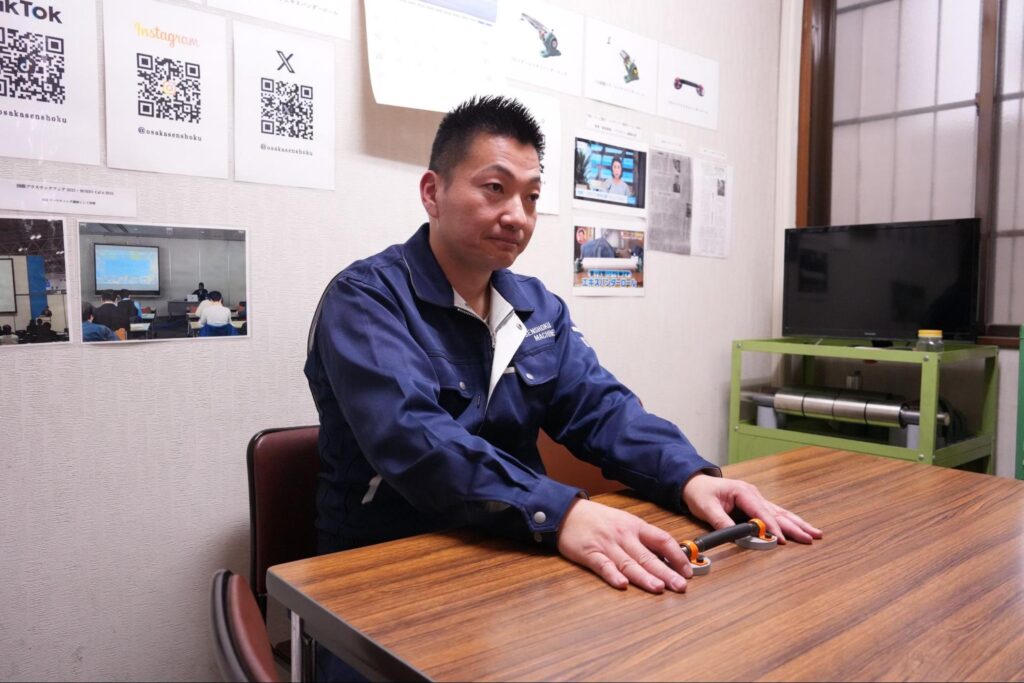

Incorporating External Technologies for Transformation

Mr. Satoshi Yamamoto joined OSAKA SENSHOKU MACHINERY CO.,LTD. in 2018. As a son-in-law, he took over the company. Having graduated from a technical high school, he spent over ten years working in equipment maintenance and sales, driven by his passion for manufacturing. However, inheriting a company was an entirely different challenge. He initially felt hesitant, questioning whether he was capable of fulfilling such a role. Yet, as he learned about the company’s history and technology, he realized that despite being a niche industry, the work held significant value. This strengthened his resolve to carry on the business for future generations.

In June 2022, Yamamoto officially assumed the position as the fourth-generation president. Given the small workforce, earning trust as the successor was a key challenge. He recalls that the most difficult aspect was navigating workplace relationships.

“As a son-in-law, I was essentially seen as an outsider by the employees. There were disagreements, and I struggled with mediation. Additionally, our company has a strong familial atmosphere, and many traditional ways of doing things remained deeply ingrained. However, I introduced external insights and pushed for transformation. We’ve gradually improved aspects that were once considered the norm.”

Such challenges are common when inheriting a business.

President Yamamoto has also actively embraced social media for marketing. By posting about the company’s products and manufacturing processes, he has attracted attention both domestically and internationally.

“The reason I started using social media was to increase awareness of our company. At the time, we had about 5,000 followers, and I had no particular resistance to using SNS. Initially, I posted about our products and expander rolls, but there was almost no response. I realized I needed a different approach, so I created multiple accounts and started sharing videos of manufacturing processes and other perspectives. Then, one day, a video I posted on Instagram went viral among international viewers.”

A reuploaded video of iron ball processing in March 2023 gained traction, and within just two weeks, the company’s follower count surpassed 10,000. As media inquiries poured in, the number surged to nearly 40,000 by the end of the month.

“We received coverage from various media outlets, including TV Tokyo and AbemaTV. All the interview requests came directly from them. It seems they were intrigued, thinking, ‘I didn’t know there was a company with this kind of technology.’ If we were a major corporation, this might not have gained as much attention, but perhaps the uniqueness of being a small-town factory made it more interesting.”

A client representative also reached out, saying, “I saw your iron ball post.” Bit by bit, the recognition is spreading. Through social media, an unknown small factory can gain attention. In today’s world, this may be an indispensable strategy.

Differentiation Through Custom-Made Solutions

Expander rolls come in various types, including fixed-curvature models, adjustable-curvature models, and specialized versions designed for use inside vacuum machinery. While they may appear identical from the outside, their internal structures differ significantly, and even a slight change in assembly can greatly impact functionality.

“We also handle maintenance and repairs for overseas-manufactured expander rolls. Typically, companies replace the original product with their own during repairs, but we focus on reusing and restoring the existing product. It’s similar to an independent auto repair shop that services vehicles outside of authorized dealerships. This allows us to maintain functionality while keeping costs lower.”

Additionally, even if no blueprints are available, the company can disassemble and reassemble products. Their expertise enables them to inspect every component and restore or improve the product to match the original as closely as possible. This capability allows them to accommodate any shape or specification of expander roll.

Although expander rolls are often mass-produced at a lower cost, OSAKA SENSHOKU MACHINERY prioritizes quality and durability, making nearly all of its products custom-made. The type of sheet material and operating conditions differ between paper and film, with variations in speed and temperature necessitating specific material choices. Using a standard specification in an unsuitable environment can lead to product failure. By listening to customer requirements and providing custom-made solutions, the company differentiates itself within the industry.

“If we had shifted to mass production like other companies, we wouldn’t have been able to compete due to differences in capital strength. However, to specialize in custom manufacturing, we must maintain unique technological expertise. Even complex and demanding projects can be handled at OSAKA SENSHOKU MACHINERY because we have the skills and infrastructure to support them.”

Because the structure and material selection for expander rolls must be tailored to the specific product, advanced judgment by skilled artisans is essential. For example, OSAKA SENSHOKU MACHINERY uses metal rolls for high-speed sheet products and durable materials for highly abrasive environments, adjusting specifications as needed.

But wouldn’t major companies have the advantage when it comes to the latest electric-powered models or angle-adjustment functions? Yamamoto shared his thoughts on this point:

“Honestly, in those areas, large corporations with greater financial resources have the upper hand. However, since we optimize existing equipment, we have a level of flexibility that major companies lack. Recently, we’ve had more opportunities to discuss technology on equal footing with patent holders and chief engineers from major firms. That said, we don’t openly showcase these technical capabilities—we compete in ways that aren’t always visible.”

Unlike standardized mass-produced items, OSAKA SENSHOKU MACHINERY’s commitment to fully custom-made products with a focus on quality and durability has earned recognition both inside and outside the industry. This reputation continues to bring in repeat business from numerous companies.

Expanding into New Markets, Including Overseas and the Metaverse

Within the manufacturing industry as a whole, a major challenge lies in how to pass down the technology behind expander rolls. Mr. Yamamoto is strongly determined to prevent its decline. The manual craftsmanship and advanced processing techniques that OSAKA SENSHOKU MACHINERY possesses are difficult to replicate with machines, making most of them irreplaceable.

“Thirty years ago, on-site craftsmen often solved problems on their own. However, today, concerns over accountability—such as ‘What if something goes wrong?’—tend to take priority. As a result, flexible thinking is restricted, and it has become more difficult to generate new ideas. Our company is committed to evolving our skills alongside our craftsmen with the mindset that we will not be outdone by cutting-edge machines or AI.”

Mr. Yamamoto believes that adopting a flexible approach in line with the times is key to technological advancement and succession. He also has aspirations to introduce their technology to overseas markets in the future.

“Expanding internationally requires significant funding, making it difficult to undertake large-scale projects at this stage. However, by leveraging social media to gradually raise awareness of expander roll technology, we hope to create new opportunities. In the long run, we also want to adapt to emerging platforms like the metaverse. We take pride in having a one-of-a-kind technology in Japan, and we will continue to develop new innovations and contribute to the growth of the manufacturing industry.”

In the niche field of expander roll manufacturing, OSAKA SENSHOKU MACHINERY continues to refine its unique expertise. With its unwavering technical excellence and forward-thinking spirit, the company is set to support Japan’s manufacturing industry for generations to come.

INFORMATION

OSAKA SENSHOKU MACHINERY CO.,LTD.

私たちは70年以上にわたる専門的技術と経験をもって

フィルム・紙・金属箔・不織布の “しわ„ “ちぢみ„ を追放します

町工場の我々にしかできないプロの技術で様々なお客様のニーズにお応えいたします

「お客様に信頼と安心を」それが私たちの想いです

- Founded in

- 1951/2/26

- No. of employees

- 10

- Website

- https://www.osm.co.jp/

- Writer:

- GOOD JOB STORY 編集部