A Kyoto-based workshop renowned nationwide for its exceptional metalworking—delivering high quality and quick turnaround to support iconic landmarks.

- Metal mining

- SDGs & Sustainability

- Unique Products & Services

- Efforts for the Community

- Consider Diversity

- Young employees are thriving

Osaka

Tokyo Midtown, Roppongi Hills, Tokyo Disneyland, Universal Studios Japan—behind these landmark destinations lies the craftsmanship of a small workshop in Kyoto.

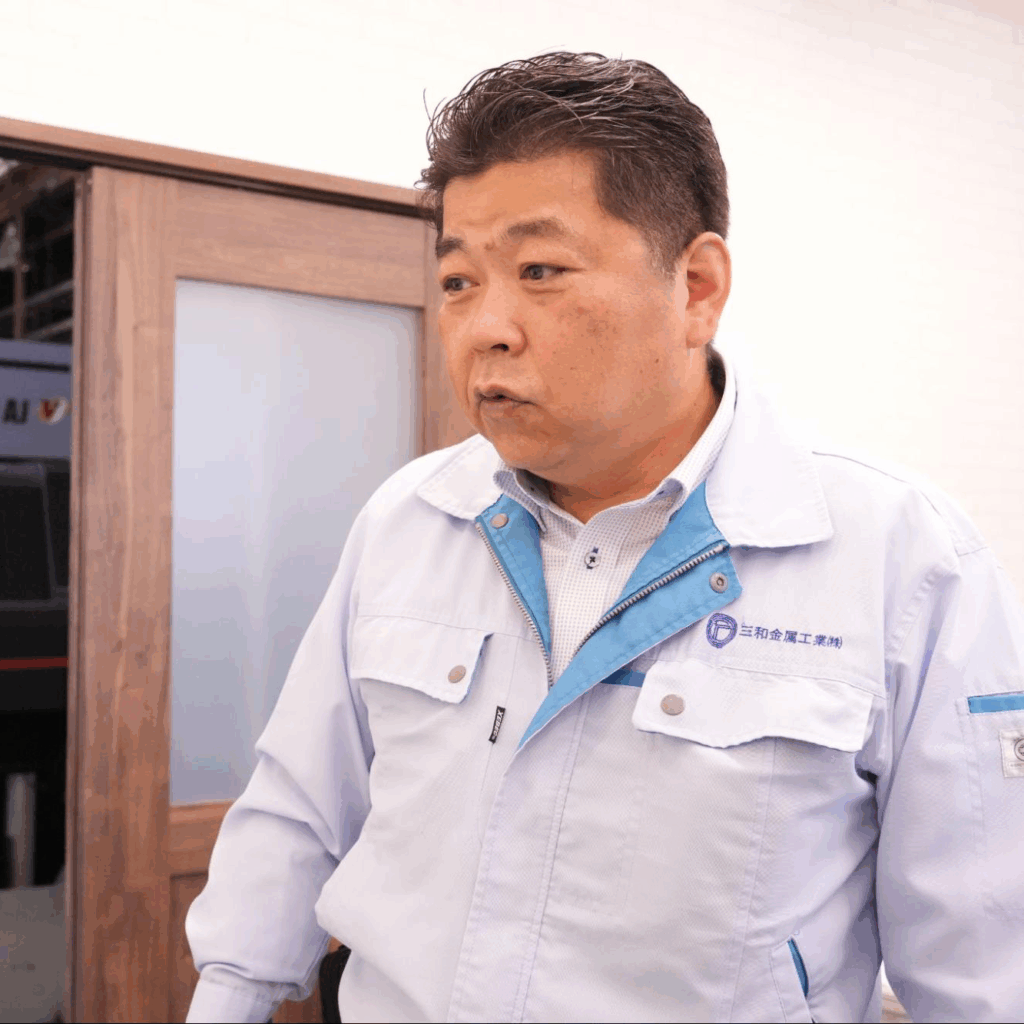

Established in 1969, Sanwa Metal Industry Co., Ltd. is a specialist in metalworking that has brought to life everything from architectural hardware and machine parts to fixtures, kitchen equipment, and video installations—all from scratch.

With four production bases across Japan, the company is praised for its unmatched speed in delivery and consistent quality even in mass production, enabling it to meet a wide range of demands from all over the country.

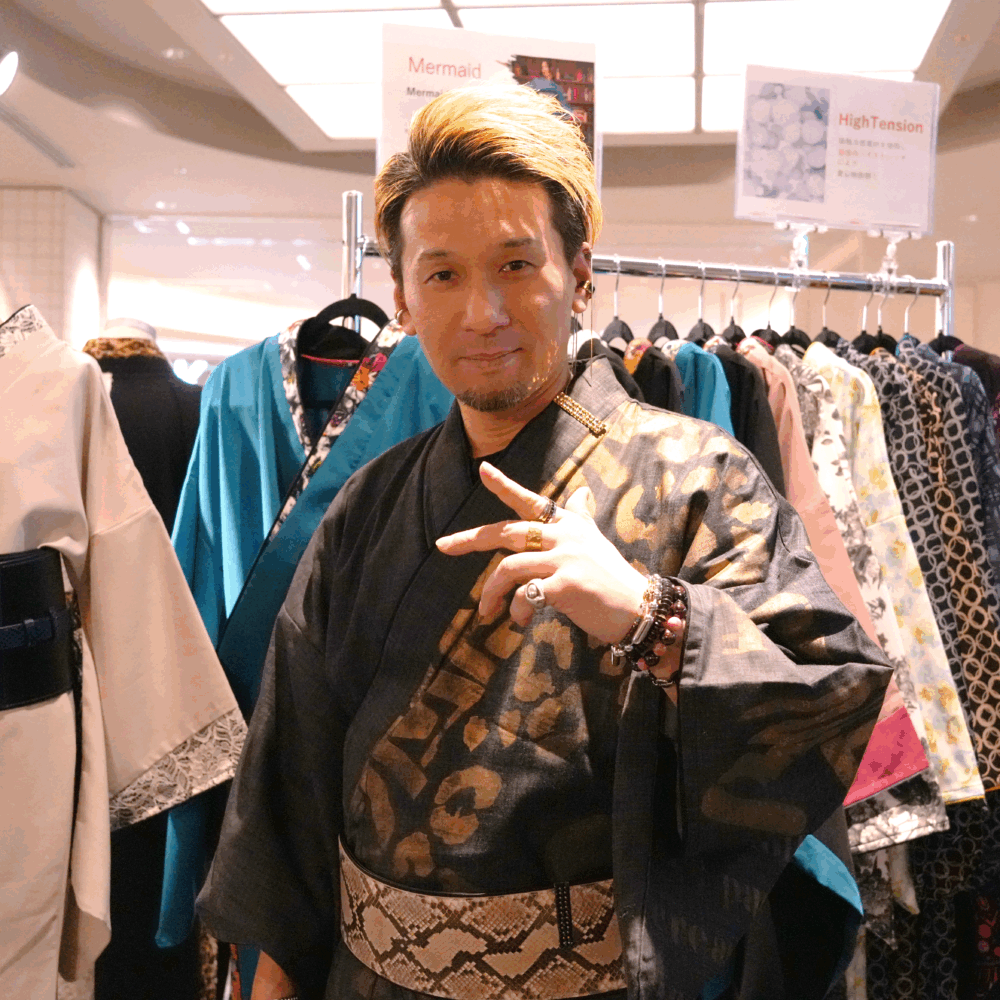

In this article, we speak with Masaaki Amo, President and CEO of Sanwa Metal Industry Co., Ltd. (hereafter referred to as “Sanwa Metal”), about the company's strengths and future initiatives.

PROTAGONIST

Masaaki AmoPresident and CEO

He experienced press working for the first time at the age of just ten.

Sanwa Metal was founded by the father of its current president, Masaaki Amo. Around the same time, his uncle established San-Ei Metal Co., Ltd. In the early days, his father handled the press work while his uncle was in charge of sales, and together they operated as subcontractors for major housing manufacturers.

From a young age, Amo frequently visited the factory—his playground was always beside the machines. Though he wasn’t consciously aiming to take over the family business, he had always loved making things.

“I first stepped on a press machine when I was ten years old. After graduating from high school, I joined the family business. The person who guided me the most back then was my uncle at San-Ei Metal. When I first came to Kyoto, it was under his guidance—not my father’s, who was still based in Osaka—that I learned how to approach sales and work. It’s been twelve years since I became president. In the beginning, I worked day and night, even on weekends. But all these years, I’ve never hesitated. I’ve simply kept moving forward, driven by my love for manufacturing.”

Several years ago, following the sudden passing of the second-generation president of San-Ei Metal, Sanwa Metal decided to make San-Ei a subsidiary, as there were no other viable options. Amo had witnessed the company’s development from the time the San-Ei site was just an empty lot. He often heard his uncle say, “One day, I want this entire area to be filled with our factories.”

“When San-Ei Metal’s future became uncertain, the first thing that came to mind was how to protect the employees, the technology, and the production base they had built. The situation was difficult, and in the end, we had no choice but to make it a subsidiary.”

At the time, a few employees remained at San-Ei Metal, but due to age and personal reasons, they gradually left. Amo struggled with the frustration of not being able to protect everyone but couldn’t bear to see his uncle’s company fall into someone else’s hands. In the end, with the companies’ histories and his uncle’s legacy in his heart, he made the firm decision to take responsibility.

Today, Sanwa Metal focuses on precision sheet metal work, as well as processing and welding of stainless steel and aluminum. The company also handles precision can manufacturing and press work. Its products are found in landmark facilities like elevators at Tokyo Midtown, Roppongi Hills, Disneyland, and Universal Studios Japan, as well as in high-precision components for medical, transportation, and public infrastructure. All of these are custom-made from scratch to meet the exact specifications of each client’s request.

“There was a time when we struggled, as work began shifting to low-cost products made in China. We did everything we could—introduced new machines, reduced costs, sped up production—but even then, their prices were half of ours. Honestly, it felt like we couldn’t compete,” Amo recalls.

However, over the course of more than ten years, a gradual shift began to emerge. As a result of choosing solely based on price, voices started to surface saying, “This just isn’t good enough,” or “We want something properly made after all.”

“Procurement departments naturally want to go with the cheaper option. But the people who actually use the products say things like, ‘This is beautifully finished,’ or ‘Very well crafted,’ and they tell us, ‘We really need products from this company.’ It’s that kind of feedback that has kept our work alive. I’m especially happy when younger people are the ones saying it’s not just about the price.”

It is a testament to the fact that Sanwa Metal’s commitment to quality has been truly recognized.

High quality cannot be achieved through technology alone.

Sanwa Metal’s strengths lie in its commitment to short lead times, strict adherence to deadlines, and an unwavering focus on quality. Long before rapid delivery became the industry norm over 30 years ago, the company had already established a culture of punctuality. It continues to accommodate same-day shipping and next-day delivery, and conducts meticulous inspections of quality and dimensions. The commitment to exceeding customer expectations has remained unchanged since the company’s founding.

“We’ve upheld the principle of delivering high-quality products reliably since my father’s time. Making a single item beautifully isn’t all that difficult. But producing 20 pieces at the same quality—that’s where it becomes challenging. To reach that level, we build experience through our daily work. Never cutting corners ultimately comes down to a battle with yourself.”

Amo believes that dedication to quality is not simply a matter of technique. Through manufacturing, he says, one learns integrity—never lying, never faking—lessons that also cultivate personal growth.

When the company first entered the elevator industry, only three people—the president, his younger brother, and a welder—had the skills to handle the complexity. In pursuit of craftsmanship, they even visited a polishing specialist in Tsubamesanjo, Niigata. As they strove to meet high standards for visual finish, their own quality benchmarks naturally rose.

“I’m deeply grateful to the professionals who generously shared their skills with us. We could never fully imitate them, but through learning, we came to understand the depth of their expertise. That’s where the real fascination lies. Whether in metalworking or any other craft, true artisans don’t scatter their focus. Instead, they pour their entire being into mastering a single technique. While metalworking isn’t considered traditional craftsmanship, it demands not only technical skill but also intellectual depth. Ten companies will produce ten different products. To truly delight our clients, we must aim far beyond what they expect.”

Sanwa Metal has grown by responding to demanding customer requirements and by fostering a workplace culture of collective effort. Amo describes the company as one “raised by both its clients and its craftsmen.”

Today, Sanwa Metal handles everything from prototyping to mass production, working with a wide range of materials such as steel, stainless steel, and aluminum, as well as complex shapes.

In 2003, the company introduced an ultra-high-speed laser processing machine, significantly enhancing both precision and speed.

Sanwa Metal’s versatility has spread through word of mouth, and in recent years, it has received orders from across Japan—from Hokkaido to Okinawa.

Hiring foreign employees has helped improve the company’s culture.

Securing skilled labor is a persistent challenge in the manufacturing industry. For many young people, manufacturing is seen as a blue-collar job and not necessarily an attractive career choice, making it difficult to recruit younger talent. Moreover, mid-career hires often come with ingrained habits from their previous jobs, and it takes time before they can become fully effective. When the company restarted after becoming a subsidiary, 19 new employees joined—but few stayed long-term.

As one strategic approach, Amo envisioned creating a “women-only factory.” The idea was sparked by seeing a woman welding on television, which inspired him to convey the message that “this is a job women can do, too.”

“In reality, I found that running a factory solely with women was difficult. Considering the potential for childbirth in the future, it was hard to assign welding tasks due to the risks of UV exposure. Today, we’re leveraging the unique delicacy that women bring to the table, and they’re playing a key role in processes like laser cutting and customer service.”

Still, the challenge of securing factory workers remained. After much consideration, the company made the decision to begin hiring foreign employees.

“At first, to be honest, I lacked confidence in communicating with foreign workers and was against hiring them. But we were severely short-staffed and had no choice but to move forward with recruitment, so we interviewed four Vietnamese applicants. Initially, we planned to hire just two as engineers, but all four turned out to be excellent, so we hired them all on the spot.

They’re not technical interns who leave after three years—they’re here for the long term, which is a huge help. Now we have 21 Vietnamese employees. When they say things like, ‘Please let us take on more work,’ it really makes me happy. They study diligently, give proper responses, and perform their work with care. They’ve become truly indispensable to our company.”The hiring of Vietnamese engineers brought about a major shift in the company’s culture.

In teaching employees who don’t speak Japanese fluently, staff became more conscious of giving clear instructions and making sure things were explained properly—areas that had previously been left vague.

This led to improvements in internal communication and interpersonal relationships.

Amo also notes that the Vietnamese workers’ sincere attitude toward their jobs and eagerness to learn has had a positive influence on the rest of the team.

To Elevate the Value of Manufacturing

Sanwa Metal Industry is currently exploring opportunities for expanding its product reach and forming processing partnerships, particularly in Southeast Asia. As part of its efforts to differentiate from competitors, the company launched the “Just Shelf” business—an innovative concept offering metal shelving units that can be custom-ordered in precise 1mm increments.

Rather than providing low-cost shelving, Just Shelf targets the premium market, similar to the high-end shelves sold in Europe. Collaborating with a designer friend, the company focused on both structural strength and aesthetic appeal in the product’s design.

“In the beginning, many people compared our shelves to cheaper alternatives and said, ‘Even if it can be customized to the millimeter, it’s just too expensive.’ But in recent years, we’ve received more praise for the quality at trade shows, and people have even told us, ‘You shouldn’t lower the price.’ That reaffirmed our decision to compete on quality, not price.”

Recently, the precision and complexity of the manufacturing process behind Just Shelf have led to new inquiries and collaborations beyond shelving.

“There are still people out there who want to work in manufacturing. I believe that nurturing those who love craftsmanship and can commit steadily to their work—and creating environments where they can thrive—is the key to the future of both manufacturing and human resource development.

I recently visited Dubai and Thailand, and I was reminded of the strong brand recognition that comes with being from Kyoto.

There are more fans of Japan than you might expect. We’ve received great feedback from overseas, and we want to continue promoting our work with even greater confidence.”

Sanwa Metal Industry is pursuing growth through the expansion of Just Shelf into Southeast Asia and by seeking partnerships with companies that value quality and excel in distribution and sales. By collaborating with such partners, the company aims to create new business opportunities both in Japan and abroad.

INFORMATION

Sanwa Metal Industry Co., Ltd.

Since April 1969, we have been engaged in sheet metal processing, primarily focusing on stainless steel and aluminum. On June 6, 1984, we transitioned to a corporate structure and established Sanwa Metal Industries Co., Ltd.

By introducing state-of-the-art machinery, we are committed to meeting our valued clients’ expectations for improved quality and reliable delivery times, and we continue to make every effort toward these goals.

- Founded in

- 1696

- Website

- https://sanwa-kinzoku.co.jp/

- Writer:

- GOOD JOB STORY 編集部