“In Pursuit of the Highest Quality” – A Renowned Store Specializing in Kyoto Confectionery Ingredients with 126 Years of Tradition

- Food & Beverage Manufacturing

- 100 Year Company

- Unique Products & Services

Kyoto

The confectionery industry in Japan has reached a plateau due to the impact of an aging population and declining birthrate. In 2023, both production value and retail sales surpassed those of the previous year as the effects of the COVID-19 pandemic subsided. However, there are concerns about losing customers due to price increases caused by the soaring cost of raw materials. Amid these challenges, I spoke with Mr. Fumihiko Nagase, the CEO of Mino-yo Co., Ltd., a company with a 126-year history. Mino-yo, a long-established Kyoto confectionery ingredient specialist, has been recognized as a model enterprise for adhering to traditional values and practices, preserving time-honored techniques, and setting an example for other businesses. President Nagase stated, "The confectionery industry as a whole is facing tough times due to a shortage of successors and the effects of climate change. We want to support confectionery businesses that are committed to delivering genuine sweets that bring comfort to busy modern people." Mino-yo is dedicated to providing the best products by using high-quality ingredients. While preserving tradition, Mino-yo's commitment to innovation has become a significant force in passing on Kyoto's food culture to future generations.

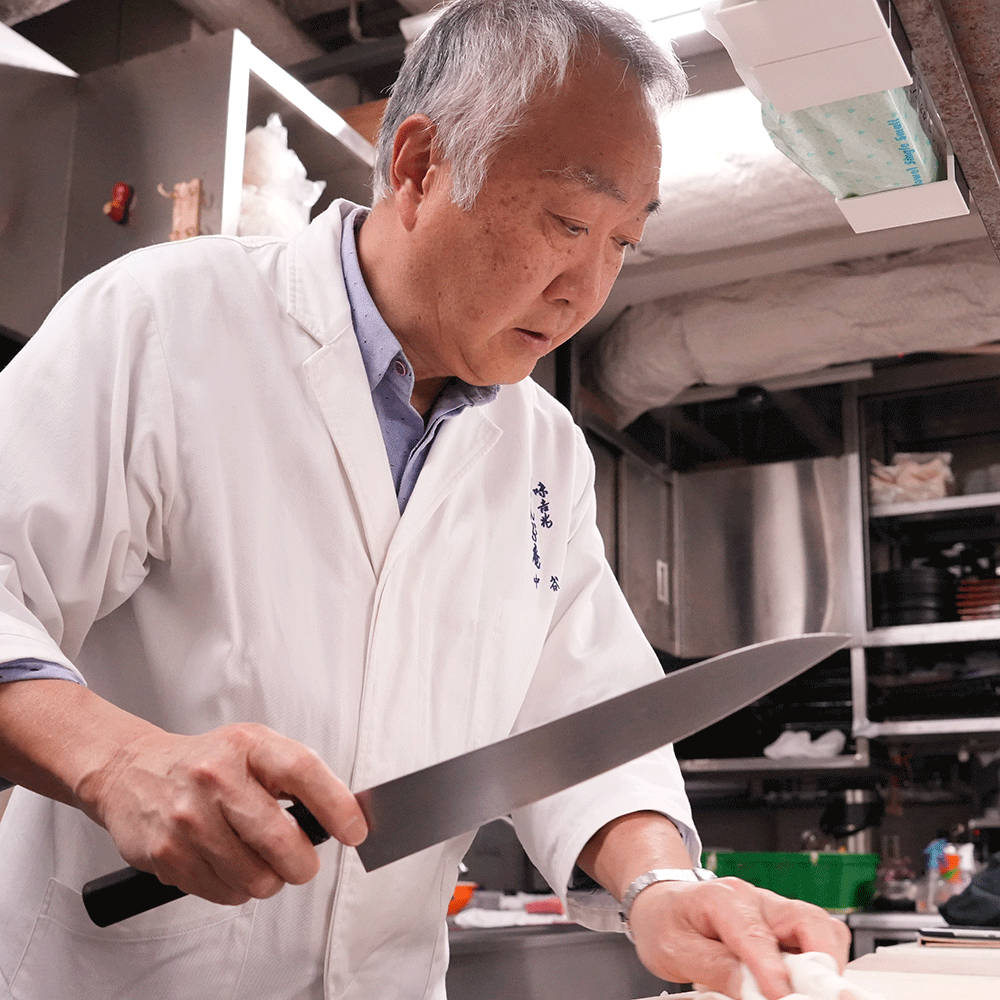

PROTAGONIST

Fumihiko NagaseRepresentative director

Striving for unparalleled high quality that sets us apart from the competition

Mino-yo Co., Ltd. was founded in Kyoto in 1902 (Meiji 35) and has been a long-established company with a history of over 126 years, primarily engaged in the wholesale of raw materials for Japanese confectionery. Mino-yo began when the first generation started peddling in Kyoto from Mino in Gifu. At its inception, the company served as a general wholesaler of Japanese confectionery ingredients, handling a wide range of materials used in traditional sweets, such as rice, chestnut kanroni (sweetened chestnuts), red beans, and leaves for kashiwamochi. Mino-yo only deals with high-quality ingredients, such as “Tanba Dainagon,” considered the finest variety of red beans, and “Shiga Habutae Mochi,” known as the king of glutinous rice. The founding principle of “providing good products using quality ingredients” is still firmly upheld today.

The soybeans used as the raw material for kinako (roasted soybean flour) are procured through direct contracts with specific farmers. By exchanging opinions on-site, the cultivation methods and harvest times of the soybeans are strictly managed, ensuring a stable supply of the highest quality raw materials. However, using only high-quality soybeans is not enough to produce delicious kinako. Roasting also significantly affects the taste and texture of kinako. Roasting is said to be particularly challenging during seasonal transitions when temperatures and humidity levels change. In hot and humid summers and cold, dry winters, the outcome of soybeans can vary even with the same roasting time. Therefore, at Mino-yo, artisans carefully observe the condition of the soybeans and adjust the roasting temperature and time each time, bringing out the maximum flavor, aroma, and smoothness of the soybeans.

A Manufacturing Facility That is Always Presentable

In 2019, Mino-yo built a dedicated soybean factory in Fushimi, Kyoto. With its own factory, the company can thoroughly pursue both flavor and quality, from the selection of soybeans to the roasting methods. Furthermore, since only soybeans are brought into this factory, there is no risk of contamination. Regarding the factory’s facilities, President Nagase states, “Cleanliness is a given. It should be a factory that we are not ashamed to show.” As soybean products are directly consumed, it is essential to ensure they are free from any foreign contaminants.”The production line is in a sealed environment, and tasks such as roasting, filling, and packaging are separated into different rooms to minimize human contact and maintain strict hygiene control.

There are two methods for roasting: direct fire and hot air. Mino-yo uses the hot air method. While direct fire roasting penetrates well, it tends to result in uneven roasting. In contrast, hot air roasting evenly heats the entire bean, preventing unevenness. This method results in finely textured and smooth kinako .

The factory uses a machine capable of roasting up to 60 kg of soybeans at a time. Compared to the 1-ton roasting machines used by large manufacturers, this is a relatively small machine. However, its smaller size allows for roasting various types of soybeans in smaller quantities, perfectly meeting customer needs. This ability to handle small batches has become a point of differentiation from other companies.

Mino-yo offers kinako not only in large bags by the kilogram but also in smaller packets ranging from 2 to 15 grams, which are not commonly seen elsewhere. Since kinako is prone to losing its aroma due to oxidation, freshness is crucial. By providing smaller packets, the kinako remains aromatic and easy to use, receiving favorable feedback from customers. To maintain the kinako’s smooth and delicious state, Mino-yo delivers it to their headquarters on the day of or the day after production. Ideally, they recommend using it the day after production, but at the very least, it should be used within three days.

Not Just a Healthy Soybean Coffee!

Mino-yo is not only dedicated to preserving tradition but has also embarked on a new endeavor by launching a soybean coffee product. This idea was realized after one of the employees brought it back from a trade show they attended. The goal was to create a new product that combines the unique flavor and health benefits of soybeans. There are over 125 varieties of soybeans in Japan, each with different tastes and flavors. It reportedly took a year to find the right high-quality soybean variety suitable for Mino-yo’s soybean coffee. The chosen soybean was “Yukihomare” from Hokkaido, known for its high sugar content and rich flavor, making it the perfect ingredient for soybean coffee. However, the initial prototype was far from delicious and tasted like plain hot water.

If the roasting temperature is too high, the soybeans burn, resulting in a strong bitterness; if it is too low, a raw taste lingers. Despite numerous trials, finding the perfect balance was challenging. The team closely observed the changes in the soybeans during roasting, meticulously checking how the aroma and flavor components formed through detailed data analysis. “We don’t want to sell it just because it’s healthy. If people buy it, we want them to think it tastes good,” they said. With this mindset, they carefully approached the development process, ultimately creating a delicious soybean coffee that all the employees could be proud of.

The unique characteristics of Mino-yo’s soybean coffee are its deep aroma with a perfect balance of rich flavor and natural sweetness from the soybeans, its light and mild bitterness, and its clean aftertaste. Being caffeine-free, it is safe for children, the elderly, and those who are pregnant. ‘It’s truly impressive to see repeat customers coming back again and again,’ says President Nagase with a warm smile. Health benefits alone aren’t enough to retain customers; taste is indeed essential.

Experience the Flavors of Seasonal Japanese Confectionery

The recent surge in prices has led to a rise in the cost of many raw materials, significantly impacting the confectionery industry. The industry as a whole is struggling. Small, independent shops and local confectioners, in particular, are being forced to reduce their purchase volumes of raw materials and downsize their operations. Additionally, the issue of finding successors to take over these businesses is becoming increasingly severe.

Mino-yo’s strengths are its extensive product range and the presence of an in-house research facility.They continue to uphold the belief of “providing good products using quality ingredients,” maintaining relationships with confectioners who seek the best. To meet the high demands of luxury confectionery shops, strict quality control is essential. Providing anything substandard would result in severe reprimands.

Japan has traditional seasonal sweets that reflect the changing seasons, such as sakura mochi for spring, kashiwa mochi for Children’s Day, and ohagi for the equinox. While convenience stores have made Japanese sweets easily accessible year-round, allowing people to enjoy seasonal treats any time of the year, there is no substitute for the taste of sweets made with fresh, seasonal ingredients. President Nagase hopes that people “will savor seasonal sweets and feel the natural charm unique to each season.”

Looking ahead, there will likely be more opportunities for traditional Japanese confectionery shops to expand overseas. When that time comes, President Nagase hopes that “people will enjoy authentic sweets made with Kyoto confectionery ingredients that prioritize quality, rather than sourcing raw materials locally.” The kinako we tasted had a rich aroma, a light, and smooth texture—entirely different from what we had tasted before. This is the real deal, crafted from years of experience. Mino-yo’s kinako is truly exceptional.

INFORMATION

Mino-yo Co., Ltd.,

As a specialty store for raw materials used in Kyoto sweets, we have continued to thrive to this day with the support of highly skilled artisans. We are committed to using domestically sourced ingredients, cherishing the seasonal essence of "shun," and striving for unparalleled quality enhancement through meticulous efforts spanning from producers to processors.

In particular, since our founding, we have been dedicated to crafting "kinako" (roasted soybean flour). In 2019, we established our own dedicated factory to meet the demands of the next generation with rigorous quality control. We manufacture a variety of "kinako" tailored to customer needs by carefully managing every aspect—from selecting soybean varieties and harvest locations to the roasting and grinding processes.

We remain steadfast in our pursuit of specialized product development and will continue this dedication into the future.

- Founded in

- 1902

- Website

- http://minoyo.co.jp/

- Writer:

- GOOD JOB STORY 編集部