Young Talent Supporting the Craftsmanship! Leveraging the Strengths of a Mid-Sized Company

- Rubber Products Manufacturing Industry

- Manufacture of electrical machinery & equipment

- Unique Products & Services

- Young employees are thriving

Osaka

The Top 500 Japanese Manufacturing Companies have seen a rapid increase in the ratio of overseas sales since the Lehman Shock, and this trend has continued. In competition with Western companies, Japanese firms are catching up quickly. On the other hand, the overall sales of Japan's manufacturing industry have remained flat at around 400 trillion yen over the past 25 years.

In this challenging market environment, Onizaki Co., Ltd. has steadily grown as a manufacturing company. In 2022, it was awarded the "Osaka Excellent Manufacturing Company Award" as a 'craftsmanship' company and was also recognized as a "Moriguchi Kadoma Manufacturing Vibrant Company."

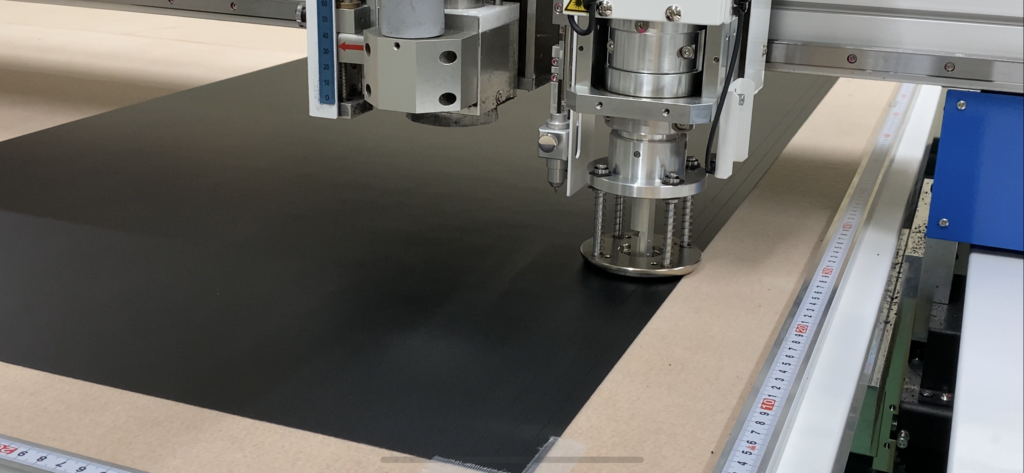

The company handles everything from processing rubber products and Thomson die-cutting to designing small electronic devices and lighting fixtures, and manufacturing parts through sheet metal, cutting, and die casting. It also manages assembly and inspection, offering a one-stop production solution. Regardless of product size or lot, the company proposes optimal solutions tailored to customer needs, gaining strong trust.

In this article, we interviewed Mr. Yuki Koizumi, the LED Lighting Section Manager, and Mr. Ken Onizaki, the nephew of the company president, to hear their thoughts on Onizaki's product manufacturing.

PROTAGONIST

Mr. Ken Onizaki / Mr. Yuki Koizumi

Connecting the Rubber Product Manufacturing and Lighting Fixture Assembly Businesses

At Onizaki, the company operates two businesses: rubber product manufacturing and lighting fixture assembly. Although rubber products and lighting fixtures may seem like different fields, many rubber products are used as seals in lighting fixtures, making the rubber business a part of the lighting business. The two businesses complement each other and support Onizaki’s overall operations.

President Ken Onizaki used to manage a factory at a company in the same industry, but 11 years ago, he founded Onizaki, taking over almost the same business operations.

“When we first became independent, we mainly focused on the business we had been involved in for years. However, since the rubber field allows for easier expansion into other industries, we are now expanding into fields beyond lighting,” says Mr. Koizumi.

After becoming independent, the company began building relationships with new clients, expanding into various industries such as cosmetic containers, infrastructure, and toy parts.

There are many companies handling rubber products, but there are surprisingly few mid-sized companies like Onizaki that can respond flexibly. In the industry, most companies are either large-scale with over 100 employees or small family-run businesses, leaving few mid-sized companies. Onizaki leverages its mid-range scale, which allows it to be agile while also being capable of mass production, giving it a unique strength.

While using cheaper materials for rubber can reduce costs, it also increases the likelihood of problems. On the other hand, using more expensive materials may not fit within the customers’ budgets.

“Rather than focusing solely on the quality of the raw materials, we prioritize a balance between practicality and cost. The choice of material is usually determined based on its use, so we don’t often experiment with various materials during the prototype phase,” says Mr. Koizumi.

Recently, inquiries have been coming from industries such as infrastructure and toys, many of which come through the company’s website. Particularly since the COVID-19 pandemic, inquiries have surged, leading to greater recognition of Onizaki’s presence. This response has reaffirmed the potential for rubber product processing to meet various demands.

“We originally started with rubber, which then led to rubber products being used in lighting fixtures. As for assembly, we were able to quickly start because we had the people, technology, and equipment necessary. Furthermore, requests for other products, such as ‘Can you make this part as well?’ kept increasing, and our business expanded rapidly,” says Mr. Koizumi.

In this way, the current lighting fixture manufacturing business was established through the requests and connections with clients. New clients continue to increase, and this trend is still ongoing.

At present, Onizaki receives optical components (such as LEDs, power supplies, and lenses) from manufacturers, and they handle the necessary outer parts, painting, and surface treatments like plating. They work in collaboration with partner companies to produce these parts and have established a one-stop system where the final assembly is carried out in-house.

We have built a long-standing relationship of trust with our partner companies in China.

When creating a product, the design team first creates 3D drawings, and manufacturing proceeds based on those drawings. There are many types of rubber used, and the optimal material is selected depending on whether the product will be used outdoors or indoors, if it will be safe for a baby’s skin, or if it can withstand chemicals.

During the prototyping phase, a small number of samples are produced using a mold specifically for prototypes. Once the samples pass the validation process, mass production is carried out at the factory in China. For rubber products, the rubber material is set into molds and shaped with heat and pressure. However, unlike small prototype molds, large molds can have uneven temperature and pressure, which can cause inconsistencies in the finished product. To minimize this issue, the final check is conducted in Japan.

Every year, company representatives visit the local facility to inspect the products and ensure there are no issues, while also strengthening their relationship with the local partners. This is more than just a transactional relationship. Through years of collaboration and mutual growth, a strong bond has been formed with partner companies, which is clearly reflected in the quality of Onizaki’s products.

A Manufacturing Industry Where Young People Thrive! The Key is Not to Over-Regulate

At Onizaki, the opinions of employees in their 30s are highly valued by management. The leadership team places importance on the ideas of younger staff, fostering an open atmosphere that encourages a spirit of challenge within the company. Even if an idea incurs some costs, as long as the individual can present a clear vision, it is not dismissed out of hand by management. This creates a sense of security and confidence, which in turn supports the growth of the younger workforce and the company as a whole.

Recently, a young employee who enjoys camping proposed an idea for a rubber cover to protect tent pegs, which was adopted. The cover uses a phosphorescent pigment, making it stand out at night, and because there are no similar products on the market, it has a high potential to attract attention. It has already been launched on Amazon for trial sales and has slowly started to sell.

In an industry facing an aging workforce, the fact that many young people gather and thrive at Onizaki is one of its strengths. By avoiding the imposition of too many rules, the company creates an environment where young employees feel comfortable sharing their opinions. The sight of them laughing together, saying, “Aren’t we a little too close?” shows the genuinely good atmosphere.

“Even outside of work, we go out for meals or enjoy spending time together if we share similar hobbies. Some of us enjoy outdoor activities, and we’ve even gone camping together. The development of this latest product actually started from the idea of a young camping enthusiast, so I really think it’s a workplace with great communication,” says Mr. Koizumi.

President Ken Onizaki is described by his nephew, Mr. Ken Onizaki, as someone who “may seem quiet at first glance, but is firm in expressing important things.” He is highly passionate about his work, always pursuing growth without becoming complacent. The company is also actively working on expanding its business both domestically and internationally.

Moving forward, the company aims to establish its own brand and expand into international markets.

With business expansion, the construction of a new office building has become a pressing issue for Onizaki. As the current factory has become cramped, a larger space is now required. Additionally, over the next five years, the company plans to establish its own brand with the aim of entering the B2C market.

“Currently, all the work we are engaged in is primarily B2B transactions between companies, but moving forward, we want to create our own brand and expand into the B2C market, particularly targeting the overseas market,” says Mr. Koizumi.

The rubber cover for protecting tent pegs, which was an idea generated by the staff and brought to life, is the starting point for expanding recognition in the general market. Onizaki also intends to broaden its focus from the domestic market to international markets. By breaking through the limitations of the domestic market and expanding globally, the company aims for further growth.

INFORMATION

Onizaki Co., Ltd.

Onizaki Co., Ltd. provides comprehensive, one-stop production solutions, covering everything from design of small electronic devices and lighting equipment to the manufacturing of parts such as rubber, sheet metal, machining, and die casting, as well as assembly and inspection. We offer optimal solutions tailored to each client’s product field and materials, regardless of product size or batch volume.

- Founded in

- 2013/7

- No. of employees

- 21

- Website

- https://onizaki-lr.co.jp/

- Writer:

- GOOD JOB STORY 編集部