Connecting the World with Japanese Embroidery Techniques: 87 Years of History and a Foot-Powered Global Strategy

- Textile industry

- Unique Products & Services

- Consider Diversity

- Environmental Issues

Osaka

Japan has a deeply rooted embroidery culture, traditionally used in items such as kimonos and obi. Each stitch contributes to the creation of beautiful designs. In recent years, embroidery has been utilized not only in traditional apparel that highlights artisanal skills but also in a wide range of markets, including corporate logos, promotional items, sports team uniforms, and event merchandise.

Since its founding in 1937, GODA EMB CO.,LTD. has been a long-established company that has continued to grow by leveraging its embroidery expertise. Starting with embroidery work for U.S. military uniforms, the company has adapted to the times, offering a diverse range of products. Today, it operates factories in China and Bangladesh and conducts extensive business both domestically and internationally.

In this article, we spoke with Gōda Yōichi, the President and Representative Director of GODA EMB CO.,LTD., about the company’s history and its expansion into overseas markets.

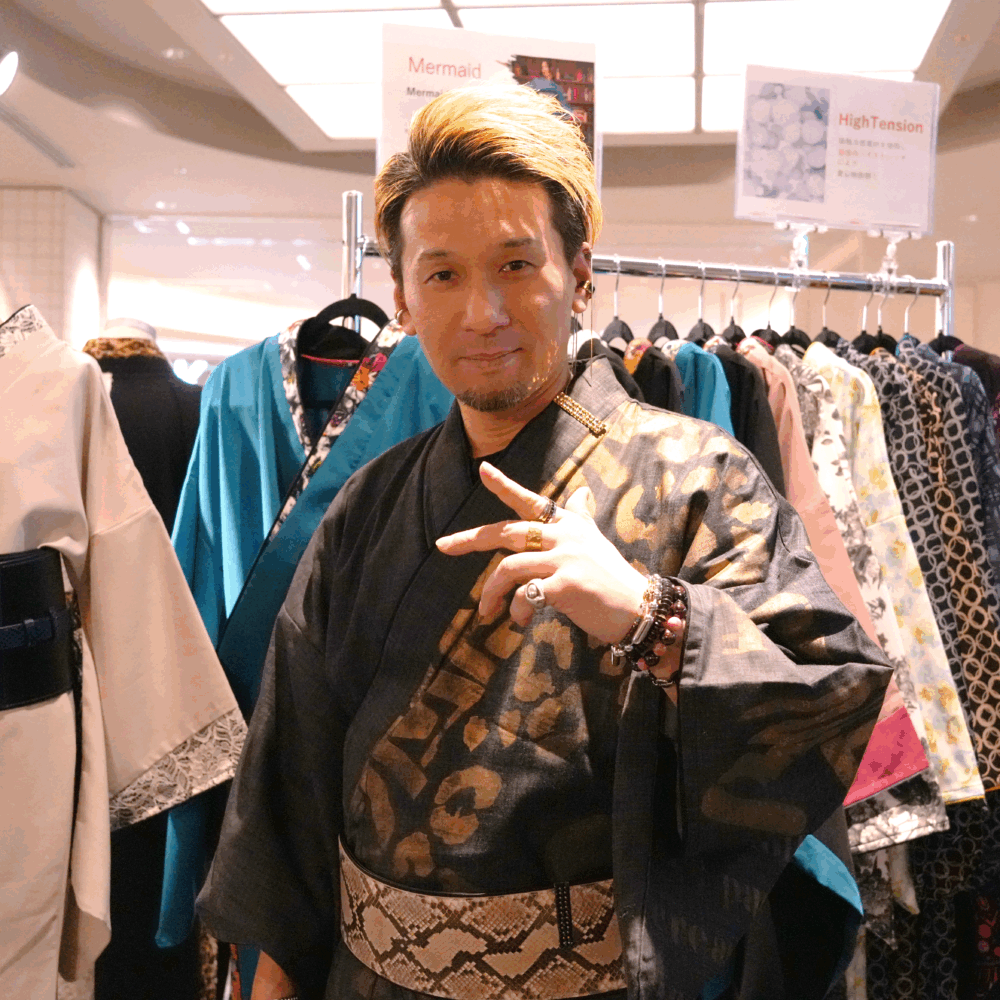

PROTAGONIST

Gōda YōichiRepresentative director

The Embroidery Business That Started with U.S. Military Uniforms

GODA EMB CO.,LTD. was founded in 1937 and began its operations during the GHQ era after World War II by embroidering U.S. military uniforms using a single-needle technique. The founder, the grandfather of the current president, perceived English alphabets as patterns and accurately replicated them despite not speaking the language. At the time, there were no competitors, and embroidery that took only a few minutes to complete reportedly sold for the equivalent of around 4,000 yen in today’s value. As times changed, the business transitioned to embroidery for apparel.

“When the company faced temporary financial difficulties, we were quick to introduce industrial embroidery machines from Germany. This significantly improved productivity, allowing us to produce products at three times the speed of manual labor. I believe we were probably the first to import German-made industrial embroidery machines,” explained the president.

During the so-called “Gachaman” era, weaving machines would make a “clank” sound, generating a profit of 10,000 yen per cycle. However, this was followed by the collapse of the economic bubble. At a time when many Japanese companies went bankrupt and work became scarce, GODA EMB CO.,LTD. managed to avoid the economic damage of the bubble burst and even expanded its business.

“Back then, fierce price competition drove many competitors to move their operations to China all at once. However, since we had already established a factory in Shenzhen, China, before that period, we were able to hold our ground while others struggled. When we entered the Chinese market before the bubble burst, some criticized us, saying, ‘Why would Gōda-san move to China when there’s still plenty to sell in Japan? Has he gone mad?’ But in the end, it turned out to be the right decision.”

Additionally, the company saw a significant increase in transactions with Europe and the United States during this time. How did a small Japanese company establish connections with American firms?

“It started when the previous president wrote a letter to an American company. He studied a book on embroidery companies in the U.S. using a dictionary and sent a letter to the author, introducing himself as a Japanese embroidery craftsman. In response, he was told, ‘Why don’t you come visit us?’ and immediately made the trip. One of the employees he met at the company later started their own business and signed an agency agreement with us. From there, our connections to the world began to expand.”

Despite Expanding into the Global Market…

Just as business transactions began to progress smoothly, another challenge emerged. Following the Plaza Accord, the rapid appreciation of the yen in Japan made domestic production increasingly difficult, prompting the company to shift its production base to China. Additionally, the company engaged in direct sales efforts at European trade fairs, securing deals for embroidered patches and establishing partnerships with top brands. Currently, GODA EMB CO.,LTD. operates four factories in China and has also established a production base in Bangladesh. However, the once-stable production in China began to feel risky after the COVID-19 pandemic.

“One major brand completely banned production in China. Although we were also producing in China, we managed to maintain our partnership because of our identity as a long-established Japanese company. That situation, however, made us aware of the risks of relying solely on Chinese production. At the same time, we recognized the increasing value of ‘Made in Japan’ products, which led us to establish a new factory in Izumi City, Japan.”

The company has also recently identified a significant market for embroidery on paper.

“We began a business embroidering goshuincho (stamp books used for temple and shrine visits), and the response exceeded our expectations. What started with a single order quickly gained popularity among goshuincho enthusiasts, leading to an increase in inquiries from temples and shrines. Additionally, products related to fan activities, such as embroidered keychains and pair rings, have also started selling well. We see particularly strong demand from customers in Kyoto,” explained Gōda.

The company has further expanded into services that embroider plain T-shirts and sweatshirts. By adding embroidery to ready-made products, they can be sold as original items, enabling efficient production. To support these services, the company introduced five new sewing machines. Gōda smiled as he commented, “There’s always a chance of failure, but that’s just part of the challenge.”

A Diversity Strategy Aiming to Build a “Bright and Happy Society”

Gōda, the third-generation president, is fluent in English and Chinese and is currently learning Spanish. After graduating from university, he worked at a textile trading company for four to five years.

“Actually, I had received a job offer from a major semiconductor company and was originally planning to work there. When I told my mother about it, my uncle, who was with the company at the time, invited me out for drinks. He persuaded me, saying, ‘If you join the semiconductor industry, you probably won’t come back.’ So I said, ‘Alright, I understand.’ At that moment, I made up my mind, thinking, ‘There’s no escaping now,’ and committed to taking over the company.”

After assuming the role of third-generation president, Gōda has focused on social contribution activities under the philosophy of “creating a bright and happy world.” These efforts include employing people with disabilities and hiring female soccer players.

“People with disabilities who join us through our employment program excel in the intricate work of embroidery. This has had a significant impact on our business. Our goal is to cultivate talent that can continue working in embroidery for years to come. Ideally, 10 or 20 years from now, we envision people with disabilities who love embroidery working here. I believe this is what contributes to creating a bright and happy society.”

The hiring of female soccer players has also proven effective, both as sports support and as a strategy for securing talent. Looking ahead, the company aims to create an inclusive workplace where people with disabilities, able-bodied individuals, athletes, and foreign nationals coexist. Every employee works toward creating a bright and happy world. As long as this core philosophy remains, the company naturally identifies what needs to be done at each stage. The employment initiatives for people with disabilities are one such effort.

Passing the Baton to the Next Generation

As the third-generation president, Gōda envisions passing the business on to a successor with the managerial skills and drive necessary to lead the company into the future.

“I have three sons, but I don’t want to tell any of them, ‘You absolutely have to take over.’ If one of them expresses a desire to do it, that’s fine. It would be ideal if we can find the right match. At this point, I don’t know how things will turn out.”

He is also considering strategies to ensure the company’s continuity, even if the successor does not come from within the family.

“The person who takes over the company shouldn’t be chosen solely based on family ties. Instead, they should be someone with both the ability to manage and the motivation to lead. While maintaining relationships with banks and shareholders, I’m also working on ways to ensure managerial flexibility and preparing for the company’s future.”

This flexible management approach is also reflected in the communication among employees. At GODA EMB CO.,LTD., significant effort is put into fostering internal interaction, with morning meetings held about twice a week.

“During these meetings, employees give short speeches, about three minutes each, creating an opportunity for them to express their thoughts. I believe this time allows employees to understand what their colleagues are thinking. We also host events, such as parties, about once a year. Recently, we’ve organized a factory inauguration party, an ‘Ai-R’ founding party, and an anniversary party. But attendance is completely voluntary. Forcing participation would make it feel restrictive, don’t you think?”

These words convey Gōda’s dedication to valuing his employees’ perspectives. On the company’s official website, he maintains a blog where he regularly shares his thoughts.

“When hiring, I encourage applicants to read my blog before applying. In the blog, I write openly and honestly about what I’m thinking at the moment. It’s gratifying when applicants resonate with the company’s philosophy and my views.”

The accessibility of the president’s genuine thoughts is crucial for fostering understanding from an external perspective. This transparency contributes to attracting talented individuals and building strong relationships with clients. Such openness may well be one of the company’s strengths.

Building the Future of “Made in Japan”

Regarding future prospects, President Gōda shared the following:

“Rather than focusing on further overseas expansion, I’d like to concentrate on strengthening our production systems within Japan. By reappreciating the value of ‘Made in Japan’ and offering high-quality products, we aim to increase orders from overseas. Additionally, we are using platforms like Instagram and other social media to showcase the appeal of our products and communicate the company’s philosophy, working to cultivate a new customer base.”

Having started with embroidery for U.S. military uniforms at its founding, GODA EMB CO.,LTD. has continuously taken on challenges aligned with changing times. Moving forward, the company plans to focus on strengthening domestic production to further emphasize the value of “Made in Japan.” These initiatives may also bring renewed hope to Japan’s manufacturing industry as a whole.

INFORMATION

GODA EMB CO.,LTD.

The GODA EMB Group is a long-established embroidery company with over 80 years of history.

We specialize in designing and manufacturing a variety of embroidery products, with meticulous attention to materials and details.

Original patches

Embroidered emblems

Goldwork (Zari embroidery)

In recent years, our offerings have expanded beyond the apparel industry to encompass products for a wide range of sectors.

Company logo embroidery

Promotional embroidered goods

Embroidered character goods, etc.

With extensive experience and knowledge, we manufacture using the latest technologies.

In addition to serving customers in Japan, we handle large-volume orders through our own factories in China and Bangladesh, ensuring timely delivery.

For inquiries about original patches, emblems, or embroidery, feel free to contact GODA EMB.

- Founded in

- 1957/4/8

- No. of employees

- 40

- Website

- https://godaemb.co.jp/

- Writer:

- GOOD JOB STORY 編集部